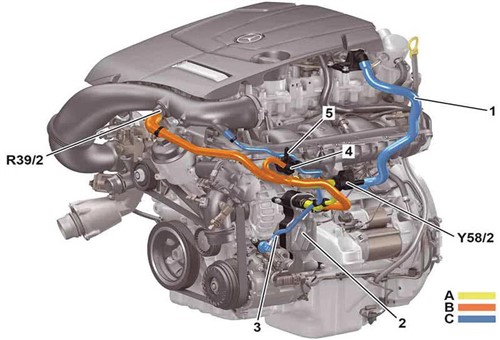

In Part 1 of this two-part article, we looked at two secondary functions of PCV systems on modern Mercedes-Benz direct injection engines. Now, in Part 2 of this article, we will discuss the operating principles of modern Mercedes-Benz PCV systems in some detail, but before we get to specifics, we need to clarify the image shown above.

This image shows some detail of the lack of working space in the engine compartment of a modern Mercedes-Benz sedan, which is representative of the lack of working space in almost all modern Mercedes-Benz vehicles. Thus, this image serves as a) a heads-up of what you can expect to deal with if you need to remove some PCV system components on most modern Mercedes-Benz engines and b) the need to be sure of your diagnoses, since removing some PCV system components needlessly could waste an entire work day.

Having said the above, let us start by looking at-

Oil separators have been a feature of Mercedes-Benz PCV systems for many years, and these components were easy to remove/replace up until the 2015 production year. Although the oil separators on pre-2015 models were reasonably reliable and effective until about 150,000 km (or so) of use, the gaskets that sealed them against the engine block were somewhat fragile and often needed replacement long before the 150,000 km mark.

To replace the oil separator gasket was easy; all it took was removing the engine covers, and removing the four E10 Torx-head bolts, removing the oil separator, and fitting a new OEM gasket before refitting the oil separator, and most mechanics could do the job in less than 45 minutes without overexerting themselves.

We only mention the above to make the point that fixing modern (post-2015) Mercedes-Benz PCV systems is vastly more difficult and time-consuming, but once you understand how these systems work, it becomes a whole lot easier to diagnose and repair a modern Mercedes-Benz PCV system in considerably less than a full work day. With that said, let us look at-

NOTE: Although the image above shows some detail of the PCV system on an M247 direct injection petrol engine, this arrangement of the PCV system is representative of the PCV systems on most, if not all modern Mercedes-Benz direct injection petrol engines. In this view-

Based on the view shown above, it might appear as if the system is relatively simple and uncomplicated, but the image does not tell the whole story. The other half of the story involves the various control and monitoring inputs that are required to make the PCV system work correctly. Briefly, the PCV system requires inputs from (among other sources) the-

-and vent line contact switch S88/5 on some models or the PZEV vent line contact switch on other models. One might wonder why a PCV system needs to be so complicated, but in this case, the multitude of control inputs is required because the PCV system is designed to operate in one of two modes, depending on the engine speed/load and the throttle position. Below are some details of how the two modes work-

Partial load operation

In this mode, the engine control unit actuates a valve that is located in the partial load vent line. During this mode, the valve is actuated by the ECU when the vehicle decelerates, which causes evacuation of the crankcase to start at the oil separator, and waste gases to flow to the intake via the charge air distributor. Most importantly, this process happens during the air/fuel mixture adaptation phase.

Wide-open throttle operation

In this mode, crankcase evacuation starts at the oil separator, and waste gases flow directly to the intake air duct. Note that the wide-open throttle part of the PCV system contains a heater element that is located in the full load vent line; the element is controlled by the ECU and is activated when the outside ambient temperature reaches a minimum threshold of 7 degrees C to prevent the PCV system from freezing up, which brings us to-

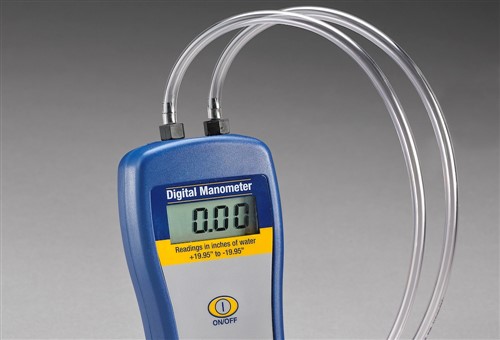

Image source: https://yellowjacket.com/wp-content/uploads/2015/03/78052-1.jpg

This image shows one example of a digital manometer, which is the most appropriate tool to use when diagnosing PCV issues on modern PCV systems. Manometers are calibrated to detect and measure extremely small pressure differentials between atmospheric pressure and both positive and negative pressures that obtain in the crankcases of internal combustion engines. Of course, you could also use an oscilloscope and a pressure transducer, but digital manometers are easier to use. Manometere also cost much less than oscilloscopes.

With the above said, let’s get back to diagnosing modern Mercedes-Benz PCV issues by listing the most common fault codes you are likely to see, these codes being-

Of these five codes, P052E is the most common, probably because overfilling an engine with oil is the most likely cause of this code. Note that this code can be triggered even if the engine is just marginally overfilled, so if you encounter this code on a modern Mercedes-Benz engine, the first step in diagnosing it should always be to verify that the engine oil level does not rise above the “FULL” mark- even by just a little bit.

If the engine is not overfilled, the (generic) steps listed below should help you find the cause of the problem-

Check the vacuum in the crankcase

With KOEO, connect a manometer to the dipstick tube, but ensure a proper positive seal. Next, start the engine and use an OEM or OEM-compatible scan tool with bidirectional controls to activate the PCV valve. If the valve works and the rest of the PCV system is in good working condition, the crankcase vacuum will fluctuate by 5 and 10 millibars.

If, however, there is no change in the crankcase vacuum as you open and close the valve with the scan tool, you will have to remove the valve to test it manually. Note, though, that the process of removing the PCV valve on many models could take between five and six hours, and more if it’s your first time removing a PCV valve from a modern Mercedes-Benz vehicle.

Check electrical values

If the PCV valve works as expected, measure the solenoid’s electrical resistance, which should be between 28 and 38 Ohms. If the measured resistance falls outside this range, replace the valve/solenoid assembly.

Verify power supply

If the resistance reading is good, verify that the solenoid has 12V available between the red and green wires. Note that this test must be done with KOEO.

Verify the ground connection

If the power supply is good, test the ground connection between the grey and yellow wires while activating the solenoid with the scan tool.

Decide on the next step(s)

This is where things get serious because if the solenoid has a good power supply and a sound ground connection but it still does not work, you'll need to replace the valve assembly with an upgraded package, which is only available from Mercedes-Benz dealerships.

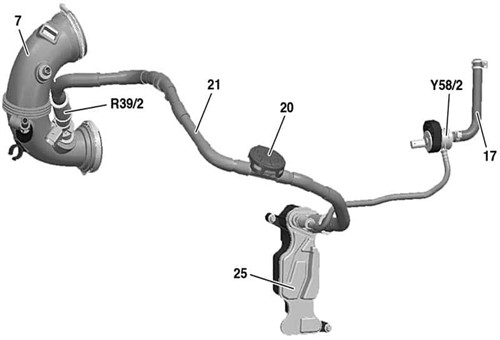

However, before you order this package, remove the entire PCV system from the engine to check and verify that all hoses and vacuum lines are open and free of restrictions. The image below shows a representative layout of PCV systems on modern Mercedes-Benz engines-

Image source: https://automotivetechinfo.com/wp-content/uploads/2023/06/lower-oil-separator-vent-line-assembly.jpg

This system may look simple, but the way it is attached to the engine makes it hugely difficult to work on or remove/install. For instance, the part labelled "25" is the oil separator, which is buried under the passenger-side engine mounting bracket, and so the only way to remove the oil separator from the engine is to remove the engine mounting bracket, which can be challenging if you have not done it before, which leaves us with this-

Since repairing or replacing PCV systems and components on modern Mercedes-Benz engines is hugely difficult and time-consuming, we must educate our customers on the importance of servicing their late-model vehicles regularly to avoid the huge repair bills that come with replacing a PCV system.

It is also imperative that we do not overfill the engines in modern Mercedes-Benz vehicles with oil since as little as 50 to 100 ml of oil can destroy a PVC valve assembly. This assembly is located low on the engine block and close to the maximum oil level, so take extreme care when servicing a modern Mercedes-Benz vehicle that the oil level does not exceed the "FULL" mark on the dipstick.

Having said the above, we hope that this article has given you some new insights into how PCV systems on modern Mercedes-Benz engines work and while these systems might sound intimidating, once you have removed and replaced a few of these systems, you should be able to do it in less than about 8 to 10 hours. Provided of course, that you follow all OEM repair steps to the letter and successfully resist the temptation to take shortcuts, which is something that never ends well.

One more thing- we do not recommend that you attempt a) a diagnosis of this system without referring to OEM-level service information and b) to attempt removing the PCV system from a modern Mercedes-Benz vehicle without the benefit of relevant and up-to-date OEM service/repair information. Without service information ready at hand, you will almost certainly route wiring and hoses the wrong way, meaning that some engine components won't fit into their respective places, which, if it happens, usually means a few extra hours of work to fix routing mistakes.

With some luck, you may never encounter issues on a modern PCV system but if you do, we recommend that you take a step back and collect/read as much information on this system as you can before you do or test anything. After all, we can only fix something if we understand how it works, but then again, we have had to learn many new things before so there is no reason why we cannot master modern Mercedes-Benz PCV systems, as well, right?