During a recent visit to a local Ford dealership, this writer happened to overhear a conversation between a service advisor and an irate customer. While this conversation took many twists and turns, the gist of it was that the customer wanted a refund of the purchase price of a fuel filler cap for his 2016 Explorer because as he explained to the hapless service advisor, “replacing the cap did nothing to resolve a persistent P0455 (Gross Leak [in EVAP System] Detected) trouble code. Despite the service advisor’s repeated assertions that defective fuel filler caps account for less than 25% of EVAP system trouble codes, and therefore, it was likely that there was some other reason for the P0455 trouble code, such as an actual leak in the EVAP system. However, the customer was having none of it, and insisted on speaking with a supervisor with “some real authority to make decisions about refunds”, but unfortunately, this writer was called away before the issue could be resolved, one way or the other.

Sadly, many mechanics also still labour under the mistaken impression that most, if not all EVAP system codes can usually be resolved by simply tightening the fuel filer cap, or by replacing the cap when that does not work. The truth is, however, that EVAP systems and particularly those on Ford vehicles, can be highly temperamental and finicky, and in this article, we will explore both the nature and inner workings of Ford’s EVAP systems in some detail. Let start with this question-

Some studies have shown that on pre-EVAP equipped vehicles, volatile and harmful fuel vapours that escape from an average passenger vehicles’ fuel tank can exceed the total exhaust emissions of most average vehicles by as much as 200% over the average useful life of a vehicle.

Therefore, evaporative emission control measures are as closely defined as exhaust emissions in all emission control regulations that are in current use around the world, and like exhaust emissions, the maximum allowable volume of fuel vapour that can be released from vehicles is reduced with each new iteration of exhaust emission regulations.

While it will be very difficult, if not impossible to prevent fuel vapours from escaping from vehicle fuel tanks altogether, modern evaporative emission control systems are vastly more efficient than ever before, and EVAP systems on most major vehicle brands can now recover over 95% of fuel vapours. This is true even in hot climates such as in Australia, where fuel evaporates at much higher rates than it does in cooler climates.

Thus, as a practical matter, a fully functional EVAP system on an average passenger vehicle can prevent several tons on harmful hydrocarbons and volatile petroleum-based aromatic compounds from escaping into the atmosphere over the useful life of that vehicle. However, while harmful raw fuel vapours are prevented from entering the atmosphere, the secondary purpose of all EVAP systems is to transport collected fuel vapours to the engine to be combusted as part of the air/fuel mixture, and as a result, harmful fuel vapours are converted into harmful exhaust emissions.

How profitable this trade-off is in terms of reduced environmental pollution is not for this writer to say, but fortunately, that is not the main topic of this article. The main topic is understanding how Ford’s EVAP systems capture, contain, and manage fuel vapours, so let us look at-

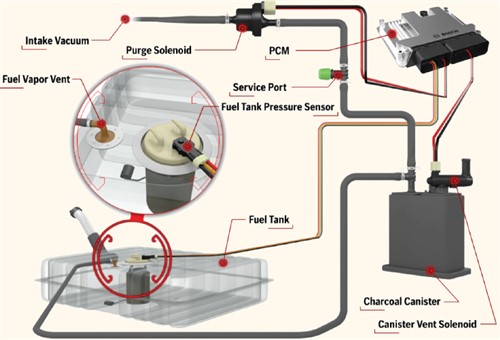

Image source: https://www.motor.com/wp-content/uploads/evap1_0317.png

The diagram above shows the main components of the EVAP systems in use on almost all Ford* applications, relative to each other.

* Note that this diagram does not apply to Ford hybrids and some conventional Ford Fiesta models, both of whose EVAP systems more closely resemble those on most KIA and BMW models in terms of both componentry and operation.

For the most part, Ford EVAP systems use the same components that most other manufacturers use, and mostly in the same way as well. Thus, all Ford EVAP systems also typically use charcoal canisters, vent, and purge solenoids, various pressure sensors/switches, and pressure-regulated fuel filer caps, but the main differences between Ford’s EVAP systems and those of other manufacturers revolve around-

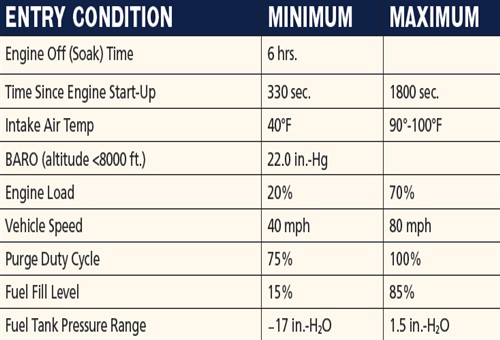

As a practical matter, Ford EVAP systems run several distinctly separate self-tests that cover several distinctly different conditions that occur in fuel tanks during normal vehicle operation. Before we get to the specifics of these phases and their associated tests, consider the table below-

Image source: Ford Motor Company / https://www.motor.com/wp content/uploads/evap2_0317.png

This table lists the enabling conditions that must be met for an EVAP system self-test cycle to complete successfully on most Ford applications. Depending on which enabling condition(s) is/are not met, or cannot be met, one or more phase tests might not initiate or might be initiated but aborted, which may or may not set trouble codes and illuminate warning lights.

However, before we get to how the different test phases work, it is important to note that before any testing can start, the ECU performs pre-programmed tests on the-

Once the ECU is satisfied that all tested components, sensors, and systems are fully functional, it initiates the so-called-

NOTE: To both avoid confusion and ensure consistency, all positive and negative pressures in the following sections will be given in millimetres of Mercury, commonly expressed as “mmHg”.

With the engine running, the ECU purges collected fuel vapour from the charcoal canister by closing the canister vent solenoid and opening the canister purge solenoid to allow the engine vacuum to "suck" fuel vapour from the charcoal canister.

During this phase, the ECU is expecting the fuel tank pressure sensor to register a slight negative pressure (vacuum) as result of the slight restriction caused by various filters in the system, as well as by the charcoal canister itself. As a rule of thumb, the ECU is expecting to see a vacuum in a range of about -3.73mmHg to about -4.47mmHg. If the fuel tank pressure sensor registers a negative pressure that exceeds 14.95mmHg, the PCM will conclude that the EVAP system is restricted, and it will almost certainly set code P1450 – “Excessive Vacuum Build-up” as a result.

Note though that a) the workhorse phase can initiate at any time when the engine is running, and b), that unlike other EVAP phase tests, the fuel level in the tank plays no role in the performance of this test.

Assuming that the fuel tank is between 15% and 85% full and that all other enabling conditions or criteria have been met, the gas vapour integrity phase test involves the ECU closing the canister vent solenoid and opening the canister purge valve to pull a strong vacuum in the fuel tank.

During this test, the ECU expects to see the fuel tank pressure sensor register a negative pressure of about -14.95mmHg: if this target value is not met, the PCM will repeat the test multiple times to confirm the failure. If after several attempts the target negative pressure cannot be achieved, the ECU will conclude that a leak greater than 1mm is present in the system, and it will set code P0455 – “Gross Leak Detected”, as a result.

If the negative pressure during this test exceeds the target value, the ECU will set code P1450 – "Excessive vacuum build-up" but be aware that on most late model Ford applications, code P0457 might also be set. This code typically appears after fuel had been added to the tank after an extended "key off" condition. Note though that in most instances of this code, the vehicle will usually display a message to check the fit and condition of the fuel filer cap before a warning light is illuminated.

Assuming that the previous phase is performed successfully and that the target negative pressure is achieved, the ECU initiates the vacuum stabilisation phase. In this test, the ECU maintains the negative pressure in the system by closing both the canister vent and purge solenoids.

During this test, the ECU expects the negative pressure in the fuel tank to remain constant; if the negative pressure increases, the ECU will set code P1450 – "Excessive Vacuum Build-up". Note though that the ECU will typically abort this particular test at this point since either, or both excessive fuel slosh and changes in engine load and speed can affect the outcome of this test.

If the previous test completed successfully, the ECU initiates the next phase by continuing to maintain the negative pressure in the fuel tank. However, this phase of the test is based on the time elapsed since the test began.

In practice, the ECU measures how long it takes the negative pressure in the tank to decay. For instance, if the negative pressure is 13.08mmHg when the test starts and this value decays to 0mmHg in only a few seconds, the ECU will conclude that a gross leak is present in the system. Similarly, if the 13.08mmHg negative pressure decays to say, 3.74mmHg over 30 seconds, the ECU will conclude that a large leak is present in the system. On most models though, the ECU will conclude that no leaks are present in the system if the negative pressure remains constant for about 30 seconds.

Note though that while Ford ECU’s use time elapsed to classify leaks, the time that needs to elapse before a leak is classified as either gross or large (up to 1mm in diameter) differs between models and production years. Therefore, it is critically important to consult reliable service information for the affected application before you draw diagnostic conclusions based on this test alone. Nonetheless, all Ford applications will indicate gross leaks with code P0455, and leaks with diameters of up to 1mm* with code P0442.

* Leaks with diameters of up to 0.50mm are detected with an entirely different test, which we will discuss later on in this article.

If the vacuum hold and decay phase completed successfully, the ECU initiates the vacuum release phase by opening the canister vent solenoid to bring the pressure in the tank up to atmospheric pressure. The main purpose of this test is to verify that the canister vent solenoid opens fully, which is determined by the rate at which the pressure in the tank comes up to ambient atmospheric pressure. Note that this period also varies between models and production years.

Once the ECU is satisfied that the pressure in the fuel tank is equal to atmospheric pressure, which typically takes between 30 and 60 seconds, the ECU closes the canister vent solenoid to allow the pressure in the fuel tank to rise.

This is accomplished through fuel slosh induced by the movement of the vehicle, the action of fuel returning to the tank (or the agitating motion of the fuel pump on return-less systems), the ambient temperature, and the temperature of the exhaust system, all of which accelerate the evaporation rate of the fuel. In most cases, the rise in positive pressure is rapid; if however, the positive pressure in the tank does not rise above 4.7mmHg, the ECU will conclude that a 1-mm leak is present, and it will set code P0442 as a result.

All the tests described up to this point use both positive and negative pressures to find gross and large leaks. Small leaks, on the other hand, require a different method of testing because their effects are smaller and take longer to manifest, so let us look at how Ford EVAP systems perform-

Small leaks are defined as leaks that are no larger than about 0.5mm in diameter, and while Ford EVAP systems still use both positive and negative pressures to test for small leaks, the implementation of the test strategies are somewhat different.

For instance, the guiding scientific principle used for small-leak testing involves the Ideal Gas Law, which states that under ideal conditions, the temperature of a gas that is under pressure will decrease at a predictable rate as the pressure decreases, and vice versa. Here is how it works on Ford applications-

While pressure-based tests for small leaks do occur during cruising conditions, a more accurate test is used as a confirmation of leaks (or confirmation of the absence of leaks) when the vehicle is stationary and the ignition is switched off. To make this system work, Ford ECU's have been upgraded to contain a built-in, dedicated "Keep-Alive" module that monitors the EVAP system without the need to energise the entire ECU.

In practice, the Keep-Alive module closes the canister vent and purge solenoids to seal the EVAP system while monitoring the fuel tank pressure sensor, at the same time. Since the Ideal Gas Law describes the relationship between the pressure and temperature of a gas, in this case, fuel vapour*, any rise in pressure translates into a predictable rise in temperature. Conversely, a decrease in pressure translates into a predictable decrease in temperature.

However, since the proximity of the hot exhaust system to the fuel tank (or high ambient temperatures) will cause a sharp increase in pressure as a function increased temperature, the system is programmed with reference to a maximum pressure/temperature threshold. If this threshold is reached, but not exceeded, the Keep-Alive module will open the canister vent solenoid to relieve most of the excessive positive pressure, which produces a sharp decline in the temperature of the fuel vapour.

To avoid false-positive results, however, the Keep-Alive module will monitor the pressure of the fuel vapour as a function of its temperature for 45 minutes to increase the accuracy of the test as the fuel cools down naturally. Cooler fuel produces fewer vapours and since the decrease in vapour temperature produces a predictable decrease in the pressure of the vapour, the Keep-Alive module will interpret sharp decreases in temperature over 45 minutes as the presence of a leak that is up to about 0.5 mm in diameter. For reference, keep in mind that the EVAP system has to pass all the phase tests described above for large (up to 1 mm in diameter) leaks before the engine off natural vacuum test can or will be initiated to test for small leaks.

* Note that for petrol vapour, a temperature change (positive or negative) of 3 degrees will produce a pressure change (positive or negative) of 1.9mmHg.

Thus, as a practical matter, the Keep-Alive module uses the known correlation between the temperature and pressure of fuel vapours to detect small leaks in the EVAP system. As a result, deviations from the known correlation pattern indicates a leak in the system which leaves us with this-

Although this article did not address the diagnostics of Ford EVAP systems, it does help to remember that Ford's EVAP systems have not changed in meaningful ways since they were first introduced, at least not in terms of a) the components used, and b), how those components work and interact with each other.

What has changed over the last few years, however, is that the programming of Ford’s ECU's has evolved to allow not only for more accurate testing and interpretation of test results but also to include more test phases to eliminate or reduce both false positives and negative test results. From our perspective as technicians, this makes the learning curve involved in diagnosing EVAP codes on late model Ford applications less steep, but the downside is that we now need to be more aware of ECU programming errors, and learn how to recognise, diagnose, and fix such errors. Thus, having reliable access to TSB’s and other service information is now as important as having a reliable smoke machine, but with some luck, the Mandatory Data Sharing Law will take care of that aspect of diagnosing and fixing Ford EVAP systems for us.