Wouldn’t it be nice if someone invented wiper blades that not only always worked as well as the example shown above, but also did so for the life of the vehicle? Well, maybe that's asking a bit too much, but we can have the next best thing, which is having wipers that last beyond a few months, or sometimes, even just a few weeks by making appropriate choices, and paying attention to detail when we replace the wiper blades on our customers' vehicles.

One “problem” we have with replacement wiper blades is that it is one of the few things whose quality and operation our customers can judge objectively after a service. As such, customers tend to judge the entire service on how well (or otherwise) the wipers work if, for instance, they hit a spot of wet weather on their way home after collecting their vehicle from us after a service.

If the wipers work as well as in the example above, the customer will not only be happy, but the customer will also likely become a regular customer. However, if the wipers do not work as well as in the example above for whatever reason, two things will almost certainly happen. The first is that the customer will return the vehicle to have the wipers replaced at our cost, and the second thing is that the customer will very likely take his future business elsewhere.

None of us can afford to lose customers, so in this article, we will take a closer look at wiper blades in terms of what makes them work, and what causes them not to work as well as expected. We will also look at why some wiper blades don’t work well right off the bat and why OEM-equivalent wiper blades work better and last longer than generic aftermarket wiper blades that supposedly work equally well on dozens of applications. Before we get to specifics, though, let us look at the three types of wiper blades in common use today, starting with-

We are all familiar with the type of wiper blade shown above since it remains the most common type of wiper blade used on vehicles built before about 2006. We also know that sometimes these wiper blades work well, while other times they do not, and often right from the moment they are installed. In some cases, these wiper blades do not sweep water from the windscreen over their whole length, or they judder and/or squeak as they move across the glass, or they do not wipe water from the windscreen in cold weather or during heavy downpours. We have all seen these things happen, but have you ever wondered why only some conventional wiper blades do this, while others do not?

There is no single reason that explains poor wiper performance in all cases, but in the majority of cases, the root cause involves the design of the metal frame, which consists of a series of interlinked arms or linkages that spread the pressure of a spring in the wiper arm evenly across the whole length of the wipe blade. Well, that’s the theory, but let’s look at why this arrangement does not always work as well as it should on modern vehicles.

In engineering parlance, the system of interlinked arms or linkages is most commonly known as a whippletree, but other names include whiffletree, doubletree, leader bar, and equalizer, with the last name perhaps being the most appropriate for modern times. The practice of using multiple links or arms to spread forces equally over large areas stems from about the late 1600s, and while we do have to take a brief step back into the past to understand why this does not always work on modern wiper blades, we do not have to go back that far back into history.

Fortunately, we only need to go back to the early 1940s, which was when car manufacturers began to design cars with curved windscreens, on which the straight and rigid wiper blades of the time did not work well. Thus, car manufacturers began using various forms of whippletrees to force wiper blades to conform to the curvatures of windscreens throughout the wiper's sweep or range of movement, with varying degrees of success.

Part of the problem (at the time) was that although windscreens were curved, most windscreens were curved in only one axis, and sometimes severely so. However, in practice, the inherent limitations of whippletrees meant that the wiper blades of the time could not follow the severe curvatures of the windscreens of the time. To “solve” this issue, car manufacturers either limited the sweep of the wiper blades severely to avoid the pronounced curvatures of windscreens or made wiper blades shorter to achieve the same effect. While this partially solved the problem, car owners were generally not impressed with the limited visibility that came with limiting the sweep of wiper blades, so let us look at-

How well, or otherwise a whippletree works in terms of following curved surfaces such as modern windscreens that are curved in two axes depends on three things. The first is the total number of linkages in the system; the second is the total force that is applied to the system, and the third is the relationship between the length and position of each linkage relative to the point at which the principal force is applied to the system.

Put differently, it means that by increasing the number of linkages in the system, the wiper blade can bend more acutely, but increasing the number of linkages reduces the force each linkage exerts on the windscreen because the total force of the spring in the wiper arm must now be divided among more linkages. The practical effects of this are a) that parts of the wiper blade can be lifted off the glass at high road speeds, and/or b) that the counter force of large volumes of water, as occurs during heavy downpours, lifts some parts of the wiper blade off the glass even at relatively low road speeds.

The result of either or both of the above conditions is poor wiper performance, but some wiper manufacturers have largely solved these problems in a simple, yet elegant and effective way. Here is how they did it-

Since all modern windscreens are curved in different ways, major wiper manufacturers have developed proprietary software and CAD (Computer Aided Design) strategies to develop whippletree systems that are largely unique to specific windscreens. These design strategies produce modern whippletree designs that still use a small number of linkages to maintain an equal pressure over the width of a wiper blade, but by using linkages with different lengths that are arranged asymmetrically over the length of the wiper blade, the overall design can be "fine-tuned" to follow the unique curvatures of a specific windscreen design.

Put differently, this means that regardless of how a windscreen is curved, a “fine-tuned” whippletree design will exert a constant and equal pressure on the rubber blade at all points over the length of the wiper blade, which eliminates the possibility that high road speeds or heavy counter forces will lift any part of the blade off the glass.

You may wonder what the point of all of the above is. Well, the point is that while advances in wiper blade design have eliminated or removed all of the disadvantages of whippletree-based wiper blades, the fact is that the new technologies/designs cannot be used on millions of vehicles on Australia’s roads for various reasons.

We need not delve into all the reasons why modern wiper blade designs cannot be used on mainly pre-2006/7 vehicles, but suffice to say that for the most part, modern wiper blade designs do not work well on these vehicles. Some of the reasons for this include (among others) excessive wind noise issues, to aerodynamic/airflow issues that cause modern wiper blades to flutter excessively at high-ish road speeds.

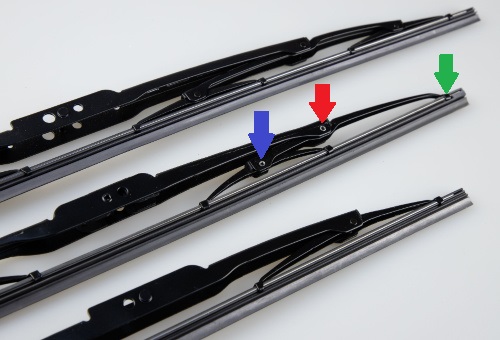

Up to now, we've said a lot about whippletrees and how they work, but let's condense all of that into an image. Consider the image below-

This image shows three different whippletree-based wiper blades, each of which is intended for use on a specific application. Let us look at the example in the middle first-

In this example, which has an asymmetric design, the distance between the pivot point indicated by the red arrow and the pivot point indicated by the blue arrow is significantly smaller than the distance between the red arrow and the attachment point indicated by the green arrow. This pattern is repeated on the other side of the wiper arm’s attachment point in the middle of the wiper blade frame.

This arrangement creates a wiper blade that bends more between the blue and green arrows than it does between the red and blue arrows. What this means in practice is that the wiper blade can easily follow the profile of a windscreen with unequal curve radii in two axes, while maintaining a constant pressure between the wiper blade and the glass throughout the wiper’s range of motion.

The example at the top of the frame shows a symmetrical design, but with two linkages on either side of the wiper arm’s attachment point in the middle of the wiper's frame. This design allows all parts of the wiper blade to bend equally, which makes it suitable for use on windscreens with a constant curve radius in one axis. The large windscreens of luxury tour buses are good examples of this kind of windscreen.

The example at the bottom of the frame shows a symmetrical design with a single linkage on either side of the wiper arm’s attachment point in the middle of the wiper’s frame. This type of whippletree design is typically much shorter than other designs, and they are most suitable for use on the rear windows of hatchbacks and some SUVs since these windows are typically a) almost flat, and b), usually, (but not always) curved in only one axis. Also, rear window wipers typically sweep a much smaller area than front windscreen wipers do, meaning that a rear wiper blade does not have to bend as much, or over the same distance as a front windscreen wiper blade.

If you’ve reached this point, you may wonder what the point of all of the above is. The fact is that there is a point, and it is the fact that more advanced wiper blade designs, such as hybrid and beam blade wipers often perform poorly for many of the same reasons that whippletree-based wipers do. You may find this somewhat surprising, given that hybrid and beam blade designs were developed precisely to address and eliminate the shortcomings of poorly designed conventional, whippletree-based wipers. Let us look at the problem with-

While "hybrid wipers" is a common term in the automotive world, it is a bit of a misnomer because these wipers do not present a real marriage between conventional wipers and beam blade wipers. In their simplest form, hybrid wipers are just conventional wipers that are covered by a plastic shell, which very often, does nothing to improve the performance of the underlying conventional wiper blade. As a matter of fact, many Asian producers manufacture hybrid wipers solely to enhance the appearance of the underlying conventional wiper.

However, the above is not the same as saying that all hybrid wipers have purely cosmetic functions. For example, hybrid wipers such as those produced by Trico, incorporate fairly advanced aerodynamic and other features that significantly increase the contact pressure between the rubber blade and the windscreen, thereby greatly increasing the overall effectiveness of the wiper.

Having said that, and as with anything else in life, you only get what you (or your customers) pay for, so we recommend that you always consider the price of a wiper blade as an indicator of the quality (or lack of it) of the blade you are purchasing or recommending, which brings us to-

As the name suggests, beam wipers are made from a flexible beam of plastic (or other flexible material) that contains a preformed, and pre-tensioned steel bar, and in a properly designed beam wiper, the force exerted on the wiper blade will be just higher than the tension in the steel bar. In practice, this means that the force applied to the wiper by the wiper arm, and the inherent flexibility and resilience of the steel bar will combine to push the rubber part of the blade against the glass with an equal force over the whole length of the blade.

However, the above operating principles leave plenty of room for mistakes and/or poor design practices, since the single most important determiners of how well (or otherwise) a beam wiper will work are the shape and tension of the preformed steel bar. In a well-designed beam wiper, the contact pressure between the rubber part of the blade and the glass will be constant throughout the wiper's range of motion, regardless of the shape or curve radii of the windscreen.

The opposite is true for a poorly designed beam wiper; an insufficiently tensioned or incorrectly formed steel bar will cause variations in the contact pressure between the wiper and the glass at various or different points in the wiper’s range of motion, leaving unswept areas on the windscreen, or causing the generally poor performance of the wiper blade.

One other aspect of beam wiper blades needs some careful consideration when you replace beam wipers on your customer's cars. You may have noticed that almost all beam wipers incorporate rather pronounced aerodynamic features, or “wings” whose function is to increase the contact pressure between the wiper blades and the windscreen at high road speeds, so what's the problem with these features, you may ask?

You may well ask because these features typically only work as both designed and intended if the wiper was designed and produced by manufacturers like Trico, whose products are OEM-equivalent and/or direct fit replacements for OEM equipment. With the aftermarket flooded with cheap, substandard knock-offs made in the Far East, you can never be quite sure what you or your customers are buying, so the beam wipers that were on promotion at the local parts store may do nothing for your customer but produce a high, piercing whistling sound even at moderate road speed.

Thus, as with hybrid wipers, stick to a reputable brand, and always consider price as a good indicator of the quality of what you are buying, which brings us to-

Now that we know a bit more about how and why wiper blades work, or not, as the case may be, the problem with the wiper blade shown in the above image should be obvious.

In this example, the red arrow indicates a gap between the rubber and the glass, which would never occur if the correct wiper blade were fitted to this particular application. As a practical matter, this particular wiper blade is subjected to excessive loads and strains in the middle, while the end hangs in free air. Over time, the additional and hugely uneven loads will cause excessive wear in the middle part of the blade, thereby degrading the performance of the wiper blade right in the driver’s field of vision.

So what causes situations like this? In this particular case, there are three possible answers-

Whatever the case may be, fitting the wrong or unsuitable wiper blades (whatever their price) to any vehicle is a really bad idea because the driver could be prevented from seeing anything in front of him when he needs to be able to see through muck and water in adverse driving conditions. So how do we always know we are not fitting wrong or unsuitable wiper blades to our customers' cars, especially when the weather is clear when we fit them, and we cannot test the wipers' operation?

Despite the above though, selecting the right wipers for any given vehicle is not that difficult, so keep the following point in mind-

The few pointers and tips listed above should make it possible for every technician to always fit the right wiper blades to any vehicle, but wiper blades sometimes fail for reasons that are beyond our control, so let’s look at some of the-

Even the highest quality wiper blades require perfect, or near-perfect conditions to perform as expected, and to do so for a reasonable amount of time. However, conditions in the real world are seldom, if ever perfect meaning that every year millions of wiper blades fail long before their expected expiry dates. Below are some of the main causes of premature wiper blade failure or poor wiper performance-

Using wrong or unsuitable wiper blades

We stated elsewhere that high-quality wiper blades are designed and intended for use in specific applications to ensure that an equal contact pressure is maintained between the wiper blade and windscreen over the length of the wiper blade. Thus, using cheap, “generic” wiper blades is almost certain to leave areas of the windscreen unswept, or where the wiper does contact the windscreen, to judder, squeak, or cause other undesirable noises/effects.

UV radiation

Although all natural rubber products are subject to attack and degradation by UV radiation, the rubber in high-quality wiper blades is treated in various ways to reduce the effects of UV radiation- unlike the rubber in cheap budget-range wiper blades. However, it should be noted that while the rubber in high-quality wiper blades is protected, how long it takes for UV radiation to degrade the rubber is directly related to how much UV radiation the wipers are exposed to. Therefore, there is no single answer to how long it will take for the Sun to destroy even the best wipes blades.

Urban pollution

Natural rubber is also highly susceptible to chemical attack by the high levels of hydrocarbons in automotive exhaust. Thus, if a vehicle spends much of its life in urban environments where there are particularly high levels of hydrocarbons in the atmosphere, the wipers on that vehicle will perish much sooner than the wipers on a vehicle that is seldom, or never exposed to high levels of exhaust gas in the atmosphere.

Note also that natural rubber is also attacked and degraded by a long list of industrial pollutants, including, but not limited to sulphur dioxide, carbon monoxide, methane, ammonia, and even ozone, which occurs naturally in the atmosphere.

Various acids

Some insects and bugs leave behind a highly acidic residue when they are splattered against a windscreen. In practice, using the wipers to clear splattered insects off the windscreen while spraying windscreen washer fluid may remove the dead insects, but few windscreen washer fluids remove the acidic residue. Thus, over time, the acidic residue accumulates as more insects are splattered, meaning that the wipers are eventually covered with acidic insect juices that literally dissolve the rubber.

The best remedy against the effects of dead insects on windscreens is cleaning both the glass and the wipers with medical-grade rubbing alcohol at least once a week, or to use/recommend a washer fluid that is specifically formulated to remove acidic residues from windscreens.

Automatic car washes

Somewhat surprisingly, automatic car washes that use rollers with stiff bristles or strap-like cleaning elements are one of the leading causes of wiper failures if the wipers are exposed. In practice, the bristles and/or straps can and do, knock the wiper arms out of alignment with the windscreen surface, and in some cases, the rollers can even break wiper blades.

When the wipers are only knocked out of alignment, the wiper blades are no longer perpendicular to the glass surface, which causes even the highest quality wiper blades to judder, squeak, streak, or just as bad, leave large areas of the windscreen unswept.

The above are just some of the most common causes of premature wiper blade failure, some, or all of which we do not take into account when we diagnose wiper blade failures. Regardless of the cause(s) of the failure, though, when wiper blades no longer work properly we have to replace them, which often raises this question-

One of the major aspects of wiper blade design concerns the amount of movement the rubber part of the blade has. Since the wiper blade bends as it follows the curvature(s) of the windscreen, the length of the frame changes, so the rubber part has to be able to adapt to these changes in length. However, the amount of movement of the rubber part is precisely calculated to prevent the rubber from stretching in some places and bunching up in others, and in a well-designed high-quality wiper blade, this particular aspect of the overall design of the wiper blade plays a crucial part in how well the wiper blade copes with high loads.

Now here is the problem with refills: the rubber part of the blade is attached by clips and retainers in specific ways to allow for the free movement of the rubber part, and loosening and retightening these clips and retainers when fitting a refill almost invariably causes some degree of interference with how the new rubber part moves in the frame. In fact, it is extremely difficult, if not always impossible, to attach a refill in the same way the original rubber part was attached to the frame, meaning that the performance of wipers with refills can never be guaranteed.

This is the principal reason why fitting refills, instead of replacing complete wiper blade assemblies is not only undesirable but also potentially dangerous when the wiper blades do not perform as expected in adverse driving conditions. So, since the safety of our customers should always be our first concern, the best thing we can do for our customers is simply not to fit refills to their existing wiper blades because the minimal cost saving is simply not worth the risk of their wipers not working as expected when they are required to, which leaves us with this-

We hope that this article has given you some new insights into how wiper blades work, and why they are more than just a legal requirement on vehicles. Functional wiper blades are, in fact, at least as safety-critical as fully functional brakes and headlights, and since we do not neglect these items during vehicle inspections, we would all do well to acquire the habit of viewing wiper blades through the same safety-focused lens when we service our customers’ vehicles.