We would all like to think that we can diagnose and repair automotive cooling systems in our sleep, so to speak. However, while this may be true for conventional vehicles, the cooling systems of EV and hybrid vehicles are so complex that if you don’t keep your wits about you, you may very well end up having nightmares when you are chasing down faults on these systems, unless of course, you have at least a basic understanding of how these systems work.

In this article then, we will take a closer look at hybrid and EV cooling systems in terms of their basic operating principles, as well as some maintenance tips and tricks. Bear in mind though that since limited space precludes a comprehensive discussion of this topic, the information provided in this article is intended to be purely illustrative. Moreover, this article will only discuss liquid cooling systems because they are more complex, so let us start with this question-

No, they are not, and while all hybrid and EV cooling systems may appear to be overly complex, these complexities can be more easily understood when one realises that the different types of hybrid and purely electric propulsion systems generate different amounts of heat in many different components. Therefore, since all components that generate heat have to be provided with a means to shed that heat effectively, the cooling system of each type of hybrid and electric vehicle differ in meaningful ways, but as a practical matter, hybrid and electric vehicles come in three main “flavours, these flavours being-

Hybrid-electric vehicles

While most major manufacturers are now producing hybrid vehicles, the best-known example is perhaps Toyota’s Prius model range, which was the first commercially successful hybrid vehicle. In short, these systems use an internal combustion engine to drive a generator that charges a battery pack, which supplies power to an electric motor to provide motive power. Under some conditions however, the internal combustion engines’ power output can be combined with that of the electric motor to provide additional power.

Plug-In Hybrid-Electric Vehicles (PHEV)

On this type of hybrid vehicle, it is possible to charge the battery pack independently of the internal combustion engine, simply by plugging the vehicle into a suitable power outlet. One other major feature of this type of vehicle, of which the Chevrolet Volt is the best-known example, is that the vehicle can be driven on battery power alone; when the battery reaches a predefined discharge level, the internal combustion starts automatically to recharge the battery pack.

Battery Electric Vehicles

This type of vehicle runs purely on battery power, which has to be replenished regularly by plugging the vehicle into an electrical outlet. The Chevrolet Bolt is perhaps the best-known example of this type of vehicle because its operating range of about 380 kilometres is the longest of all purely electric vehicles. Of the three main types of hybrid/electric vehicles, the Bolt has one of the least complex cooling systems because it does not use an internal combustion engine.

The above descriptions are necessarily very brief, but since this article is intended to discuss the cooling systems of hybrid and electric vehicles, let us look at the cooling system on one example of each type of vehicle in some detail, starting with the-

Since Prius vehicles are series-parallel hybrids, they have more complex cooling systems than either series or parallel hybrids. In simple terms, series hybrids use only motive power from the electric motor for propulsion, while on series-parallel hybrids, the electric motor and internal combustion engine can deliver motive power either simultaneously, or independently of each other.

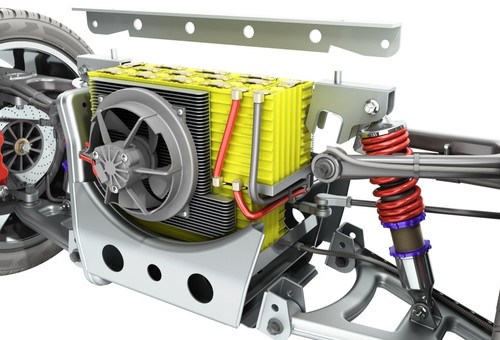

Thus, to keep everything in a Prius cool, the cooling system is a complex system that is centred on a split radiator, half of which serves the internal combustion engine, while the other half serves various electronic/electrical components. In terms of specifics, a Prius cooling system consists of 5 cooling circuits, 16 major components, 20 coolant hoses, and 2 electrically operated coolant pumps that are arranged in the following manner-

Internal Combustion Engine Cooling

This part of the cooling system is made up of 4 separate cooling circuits that are connected to the top part of the radiator, and collectively, these 4 circuits are made up of 11 major components and 14 coolant hoses that serve the following components/systems-

Power Electronics (PE) and Transaxle Cooling

This part of the cooling system is connected to the lower part of the radiator, and consists of a single cooling circuit that serves to manage the heat generated in the transaxle and various electrical components, including the power electronics. Note that this part of the system has 5 major components, and 6 coolant hoses.

High Voltage Battery Pack Cooling

Unlike many other hybrid applications that use cooling plates or heat sinks to manage the battery pack’s temperature, Prius models use several fans to draw air from the passenger compartment, and to circulate this air around and over the battery pack before pushing the air out of one-way check valves in vents that are located in the quarter panels.

The cooling systems of Volt models are arguably the most complex cooling systems in automotive use today, because it contains most of the components found in Prius and other hybrids, in addition to 4 liquid-cooled components that are for the most part unique to Volt models, these components being-

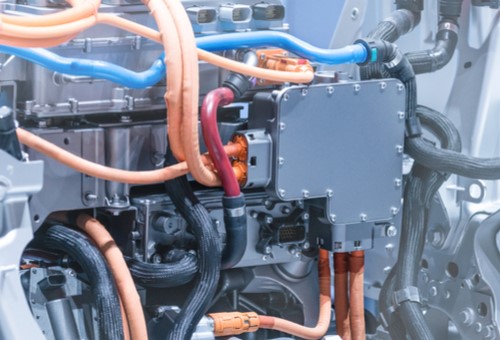

In terms of specifics, the cooling system on Volt models consists of 3 electrically operated coolant pumps, 25 other major components, and 31 coolant hoses to create 7 separate cooling circuits that are arranged in the following manner-

Internal Combustion Engine Cooling

Late model Volt models have 3 parallel cooling circuits that are connected to the internal combustion engines’ radiator, and between them, these circuits have 11 coolant hoses and 7 major components, including a mapped electro-mechanical thermostat that is controlled by the ECU with pulse width modulated signals. These cooling circuits are arranged as follows-

Power Electronics (PE) and Transaxle Cooling

While the power electronics and transaxle share a single cooling circuit (circuit #4) that uses part of the A/C condenser as a heat exchanger, this circuit has 6 major components and 10 coolant hoses.

High Voltage (HV) Battery Cooling/Heating

The high voltage battery pack uses a single cooling circuit (circuit #5) that incorporates a coolant chiller that is a part of the A/C system, and a coolant heater that is made up coolant manifolds and coolant plates through which the coolant circulates. Note that since these coolant passages are very small, they clog up very easily.

High Voltage Cabin Heating

The cabin heating system uses two circuits, one of which (circuit #6) passes through an external electronically controlled heater, and one (circuit #7) that is spliced into the internal combustion engines’ cooling system to reduce warm-up time of the cabin in low temperatures.

Purely electric vehicles like the Bolt have relatively simple cooling systems, since there is no internal combustion engine to make matters difficult. In the specific case of Bolt models, the cooling system consists of 3 cooling circuits that are arranged in the following manner-

Bolt EV Power Electronics (PE) Cooling

The power electronics use a single cooling circuit that is connected to a dedicated heat exchanger. This system has 7 major components and 10 coolant hoses.

Bolt EV High Voltage (HV) Battery Cooling/Heating

The battery pack’s cooling system resembles that of Volt models, in the sense that it uses an external coolant heater, and a coolant chiller that is part of the A/C system. Actual cooling/heating of the battery pack takes place via cooling plates, which like those on Volt models, clog up very easily.

Bolt EV High Voltage Cabin Heating

The cabin heating is managed by a single cooling circuit that is connected to an external heater that heats the coolant before it passes through a heater core, from where the heated air is distributed throughout the cabin via vents and ducting.

So now that we have a basic idea of how the coolant systems on hybrid and electric vehicles are arranged, let us look at some-

It should be noted that to diagnose, service, and repair hybrid and EV cooling systems without causing damage to components, you almost always require OEM service information and diagnostic equipment. However, reasonably comprehensive OEM service information can be purchased from several sources, such as www.nastf.org , but be aware that subscriptions to this resource is rather expensive.

Nonetheless, any reasonably competent technician should be able to perform basic inspections and servicing procedures on most hybrid/EV cooling systems, and provided that the following is kept in mind, it should be possible to offer this service to increase maintenance sales-

Use the correct coolant

While each vehicle manufacturer recommends that the same coolant be used in all cooling circuits, it must be noted that additional warnings and precautions usually apply to cooling circuits that do not serve the internal combustion engine.

For instance, all manufacturers insist that only new coolant of the correct grade and type is used, and that it is mixed in a 50:50 ratio with distilled or de-ionised water only. Using water from other sources, such as taps, can cause the following issues-

Note that both of the above conditions will set various trouble codes that may not be recoverable with generic scan tools. Be aware that some of these codes could cause the entire high-voltage system to be disabled, which is a condition that can generally only be rectified by dealerships.

However, unless a catastrophic coolant loss had occurred, routine coolant replacements in hybrid and/or electric vehicles are relatively rare events in the lives of these vehicles. For instance, Toyota recommends that the first coolant replacement be performed after 10 years or 160 000 km, and then every five years or 80 000 km thereafter. Other manufacturers recommend similar coolant replacement intervals, with Nissan stating that the coolant must only be replaced every 200 000 km.

Pressure testing

While all manufacturers of hybrid and electric vehicles generally allow pressure testing of cooling systems, it should be noted that in some cases, the working pressure of some cooling circuits is as low as 35 kPa, as opposed to the more usual pressure of about 140 kPa that is common in internal combustion engines.

Be aware though that exceeding the safe working pressure of any cooling circuit during a pressure test could cause coolant leaks that could in turn cause the deactivation of critical systems should the coolant level drop below a minimum allowable level.

Purging the cooling system

On many hybrid and electric vehicles, the only way to refill the cooling system is to use a dedicated cooling system vacuum pump to purge the system of all air. However, Toyota’s cooling systems can be purged via dedicated purging valves, but even so, the refilling procedure should not be attempted without access to OEM service information, since one or more coolant pumps need to run for varying lengths of time during the process.

This is particularly important on Prius models, since air locks or bubbles in the inverter coolant circuit can cause up to 17 trouble codes that can only be recovered with OEM scan tools and software.

Beware hose clamps

Be aware that on many, if not most OEM coolant hoses, the spring clamps are either incorporated into the hose, or glued onto the hose. Thus, when coolant hoses are disconnected for any reason, great care must be taken not to rotate or wrench spring clamps to prevent damaging or even destroying a coolant hose. Generally speaking, if a hose clamp needs to be replaced, the entire hose must be replaced.

Pay attention to active shutters

The cooling systems of almost all late model hybrid and electric vehicles are now fitted with active shutters to both improve and control the airflow through radiators at high road speeds. Note therefore that since shutter failures and/or malfunctions can cause the overheating of components, and possibly the subsequent failure and/or deactivation of critical systems and/or components, it is imperative that a diagnostic check of all shutter systems be performed during any servicing and/or maintenance procedure(s) on the cooling systems of shutter-fitted vehicles.

This is particularly important in cases where overheating related trouble codes are present, since the fault is usually more likely to involve shutter malfunctions than failures of actual cooling system components.

There is no doubt that the number of hybrid and electric vehicles on Australia’s roads will increase every year, which means that you will likely be confronted by cooling system issues on these vehicles sooner than you may have wanted. However, the upside is that these types of vehicles represent excellent and potentially profitable new business opportunities, and since OEM service information is available, you may want to learn everything you can about hybrid and EV cooling systems now, before your competitors get the jump on you