In Part 1 of this two-part article, we discussed the basic operating principles of direct petrol injection as it applies to modern Mercedes-Benz vehicles, and now in Part 2, we will discuss the finer workings of the piezoelectric fuel injectors that make the stratified-charge injection system as efficient as it is. We will also discuss the importance of using only Mercedes-Benz spark plugs, as well as the requirement to index the spark plugs correctly to avoid potentially fatal engine damage. Let us start with this question-

In 1880, two French physicists, Jacques and Pierre Curie, discovered somewhat by accident that some solid materials, which included quartz crystal, could generate electrical charges or currents when a mechanical load or stress such as pressure, was applied to them. The most interesting thing about this discovery was that in the case of quartz crystal, the electrical currents or charges it generated were directly proportional to the load or stress applied, while the crystal expanded rapidly, albeit microscopically, at the same time.

On a purely practical level, these properties of quartz crystal were very helpful when automotive engineers needed to design super fast-acting and accurate fuel injectors.

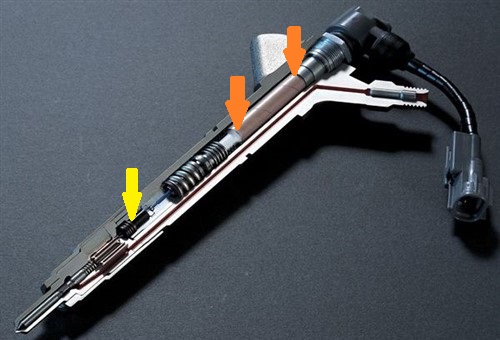

The two physicists named this process the “Piezo effect”, using a word from the Greek language that means to squeeze or press, but let us look at how the Piezo effect works in modern Mercedes-Benz fuel injectors in some detail. Consider the image below-

Image source: https://www.ammstar.com.au/wp-content/uploads/2019/10/mercedes-benz-mechanic-melbourne-.jpg

This cutaway view of an OEM (Mercedes-Benz) piezoelectric petrol injector shows the layout of its internals. In this view, the distance between the two orange arrows indicates the length of the piezo stack that consists of 400 (or sometimes more, depending on the application) ultra-thin slices of quartz crystal. The yellow arrow indicates the amplifying chamber that uses hydraulic principles to increase the effective injection pressure. Here is the short version of how these injectors work-

Although the expansion of each quartz slice in the piezo stack is barely measurable, the cumulative expansion of all the quartz slices in the piezo stack creates a movement of the injector pintle of about 0.1016 mm. In practice, the combination of this small injector opening and the fuel pressure that can be as high as 250 bar creates fuel droplets that are several orders of magnitude smaller than the smallest fuel droplets even the most advanced port injection systems can produce, which greatly improves the mixing of the fuel mist and intake air in the cylinders.

Nonetheless, when pressurised fuel enters the injector, the fuel pressure is in a state of equilibrium throughout the injector. When the engine control module applies a voltage to the piezo stack, all the quartz slices expand at the same time, and the resulting force then acts on a lever and spring system to lift the injection pintle of its seat to allow fuel to be sprayed into the cylinder. When the engine control module removes power from the injector, all the quartz slices contract at the same time and by the same amount, which ensures that the injector closes fully to prevent fuel leaking through the injection nozzle.

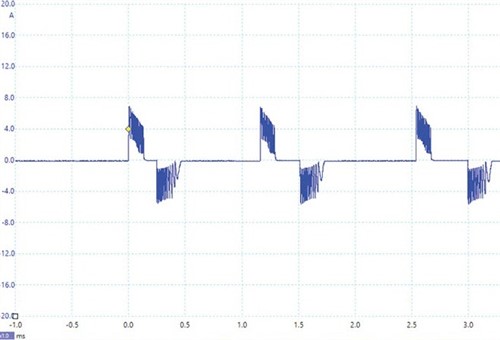

More importantly, though, the single biggest advantage of piezoelectric injectors is that they act almost 5 times faster than conventional electric solenoid-controlled injectors do, which makes it possible to perform up to three injection events in significantly fewer degrees of crankshaft rotation than is possible to achieve with conventional injectors. The image below shows a known-good waveform of three injection events (constituting one main injection event) occurring in less than 50 degrees of crankshaft rotation-

Image source: https://automotivetechinfo.com/2023/01/mercedes-benz-direct-fuel-injection/

In this actual waveform, the vertical axis shows the current draw at nearly 8 amps, which is normal for modern Mercedes-Benz injectors, while the horizontal axis shows a cumulative time-lapse for the three injections of just more than 3 milliseconds, which illustrates the very short switching times of these injectors. It is worth mentioning though that this waveform is an example of what waveforms of injection events on a modern Mercedes-Benz spray-guided injection system should look like since injector “ON” times vary somewhat, depending on the engine load and speed, which brings us to the topic of-

Perhaps the single most important thing to remember when servicing Mercedes-Benz piezoelectric injectors is that they work at much higher voltages than conventional injectors do. As a practical matter, the engine control module supplies the injectors with control voltages that range from about 140V to more than 200V, which is sufficient to electrocute a healthy person fatally. In addition, the fuel system generates pressures that range from about 130 bars to more than 250 bars, which is high enough to slice through human skin and tissue like a scalpel, so exercise extreme care when working with Mercedes-Benz OEM injectors.

NOTE: Given the above, it should be understood that it is imperative to wear appropriate PPE such as properly rated (up to 1000V) and approved gloves and eye protection when working with Mercedes-Benz petrol injectors to avoid sustaining serious personal injuries, or worse, incapacitating injuries.

Also, keep in mind that the piezo stacks are extremely fragile, meaning that just the act of pulling the injectors from their holes in an aggressive manner can break the quartz crystal elements. In fact, the best thing to do is never attempt to remove the injectors unless it is necessary, and even then, extreme care should be taken to protect the injectors against mechanical shocks. If the injectors cannot be removed by gentle pulling action, apply a liberal amount of penetrating spray, and wait at least 20 minutes before trying to remove the injectors again.

While this can be a time-consuming process, tools such as sliding hammers should not be used to remove piezoelectric injectors because such tools are guaranteed to destroy the piezo stacks in the injectors, which brings us to the topic of-

WARNING: All of us have disconnected the connectors on conventional injection systems while the engine was running. While doing this can quickly identify a faulty injector, disconnecting a piezoelectric injector on a modern Mercedes-Benz vehicle while the engine is running will almost certainly destroy the injector(s).

Having said the above, we must add that it is not advisable to test any fuel injector in any way unless relevant OEM service information calls for specific tests and checks to be performed. Assuming that there is such a call, the first step should be to use a low-amp amp probe and a digital storage oscilloscope to obtain waveforms (like the ample shown elsewhere) of suspect injectors to verify that suspect injectors are indeed defective, or not, as the case may be. Note, though, that connecting an oscilloscope directly to injector wires will damage the injectors.

However, symptoms like rough idling and loss of engine power are not always caused by defective injectors. In some cases, such as when the fuel pressure is abnormally low, the injectors will still open on the intake stroke, as opposed to on the compression stroke. This is a failsafe measure to draw at least some fuel into the cylinders because the cylinder compression might be too high to allow the injectors to inject fuel into the cylinders during the compression stroke when the fuel pressure is low.

Be aware that it is at this point where injector service or repair often goes wrong if one or more injectors have to be removed for whatever reason. Here is why-

Injectors only fit in one hole

All the injectors on a modern Mercedes-Benz engine are coded to the cylinders they are installed in when the engine is first assembled in the factory to eliminate the effects of small differences in the operating characteristics that exist between injectors.

Therefore, it is imperative that all removed injectors be reinstalled into the holes they came from to prevent things like random or persistent misfires, cylinder power contribution issues, rough idling, and pre-ignition or engine knock under some operating conditions.

All injector seals must be replaced

Mercedes-Benz specifies that all the seals on both the injector and the cylinder head must be replaced with OEM parts whenever an injector has been removed from the engine. It is worth noting, however, that a) these injectors take up to six seals each, and b), the seals can only installed with a special seal-fitting tool if you don’t want to damage them.

The other problem with injector seals is that the bores in the cylinder head can only be effectively cleaned with specially designed brushes that are available from Mercedes-Benz along with the seal-fitting tool. Be aware that installing an injector into an improperly cleaned bore will always damage the seals, so unless you have access to these special tools, we do not recommend that you remove injectors from any modern Mercedes-Benz engine until you have the required tools ready at hand, which brings us to-

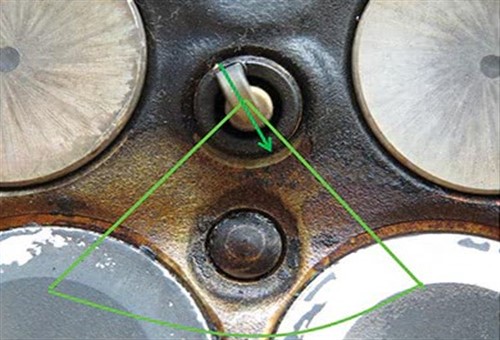

The importance of using only OEM spark plugs cannot be overstated because using aftermarket spark plugs can cause fatal engine damage. Consider the image below-

Image source: https://automotivetechinfo.com/2023/01/mercedes-benz-direct-fuel-injection/

Note the orientation of the spark plug’s electrode; the open end containing the gap is pointing almost directly at the tip of the injector. This is not by accident- it is by design to ensure that the ignition spark is exposed directly to the part of the cloud of fuel droplets that contains the most fuel relative to air. Also, note the distance that the electrode extends into the combustion chamber. Now consider the image below-

Image source: https://automotivetechinfo.com/2023/01/mercedes-benz-direct-fuel-injection/

This image shows an aftermarket spark plug installed, and while the spark is still exposed to the fuel cloud, the closed end of the electrode interferes with the propagation of the combustion flame. This orientation of the electrode effectively splits the nascent combustion flame into two parts, which greatly reduces its ability to ignite the lean layer of the stratified charge.

Moreover, aftermarket plugs are not designed to cope with the extremely high combustion temperatures of modern spray-guided stratified combustion, even if your local parts outlet says they are, so most, if not all aftermarket plugs tend to overheat severely. The consequences of this could be dire because the glowing electrodes are hot enough to ignite the fuel injected during the first and second injection events.

In practice, the compression ratios of modern Mercedes-Benz engines are on the high side, so the premature ignition of the first and second injections is roughly analogous to hydro-locking the engine while it is running. Some effects of premature ignition include broken pistons, melted pistons, and bent and broken connecting rods, all of which usually result in catastrophic engine failure. So, how to prevent this from occurring?

The only reliable way of preventing fatal engine damage is to use only OEM spark plugs that are recommended by Mercedes-Benz for use on a particular engine. Here is why-

All Mercedes-Benz OEM spark plugs are made so that when they are torqued down to their specified torque values, the open ends of the electrodes will always point (almost) directly toward the tip of the injector, assuming of course that the correct OEM plugs are fitted. It might seem like black magic, but in reality, Mercedes-Benz spends vast amounts of money and effort to ensure that the third parties who make their spark plugs follow procedures to ensure that Mercedes-Benz spark pugs are oriented and indexed correctly when they are fastened to their specified torque values. Based on this, it goes without saying that failing to torque OEM spark plugs means that they are not indexed correctly, and engine failure could occur shortly afterwards, which leaves us with this-

While it is entirely possible for competent mechanics and technicians to diagnose most, if not all issues and malfunctions on modern petrol direct injection systems, it would be a mistake to underestimate the complexity of these systems.

Actually resolving issues and malfunctions on these systems is another matter entirely but if you have access to relevant service and repair information, and Mercedes-Benz-specific software and the equipment to run it, you have a good to excellent chance of fixing these modern petrol injection systems. After all, spray-guided stratified charge petrol injection is just another new technology we have to master just like we mastered many other new technologies, so be confident, be brave, and prepare to climb this very steep learning curve.