If you are new to the car repair industry or have not had much exposure to Nissan's CVT (Continuously Variable Transmissions), you have probably not heard all the arguments, opinions, and controversies about the reliability (or otherwise) of these transmissions that now feature as the only transmission option in many Nissan products.

Note, though, that despite the many possible arguments and opinions this article can advance about both the reliability and desirability of Nissan’s CVT transmissions, it is not the intention of this article to do so. The only purpose of this article is to explain the inner workings of Nissan CVT transmissions to mechanics who have not had much, if any exposure to CVT transmissions in general and Nissan’s CVT transmissions, in particular, so let us look at the-

While there are some differences in design specifics between Nissan's CVT transmissions and those of other manufacturers, all CVT transmissions work in much the same way, although the so-called rubber band effect is more noticeable in some versions of CVT transmissions than in others. We will say more about the rubber band effect later on, but for now, let us consider the graphic below-

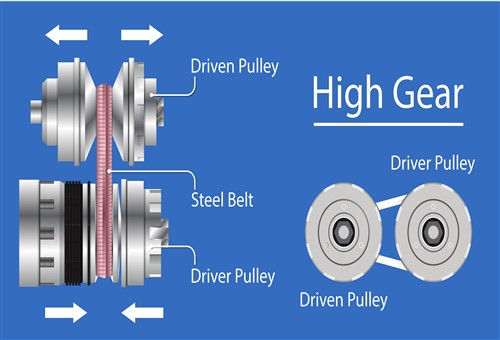

This graphic shows some detail of how Nissan’s CVT transmission works, but let’s look at the labels. In this case, the driver pulley attaches to the engine and, therefore, it rotates at engine speed. Above the driver pulley is the driven pulley, so-called because it is driven by the driver pulley via the steel belt.

To make this arrangement work, the sheaves of both pulleys are moveable, in the sense that the sheaves can be pushed closer together, or pushed apart by computer-controlled hydraulic actuators to change their effective diameters. So, if the driver pulley’s effective diameter increases, the driven pulley’s effective diameter will decrease by the same amount to maintain the chain’s tension. In the graphic above, the driver pulley’s effective diameter is at its biggest, while the driven pulley’s effective diameter is at its smallest.

This configuration is analogous to how the different-sized gears in a manual transmission work together to produce that transmission’s gear ratios. As one moves through the gear ratios in a manual transmission, different-sized gears are brought into contact with each other. As the ratios between the gears change, the amount of power the engine transmits to the final drive decreases as the ratio between the gears get bigger, and the output shaft's rotational speed increases. Now consider the graphic below-

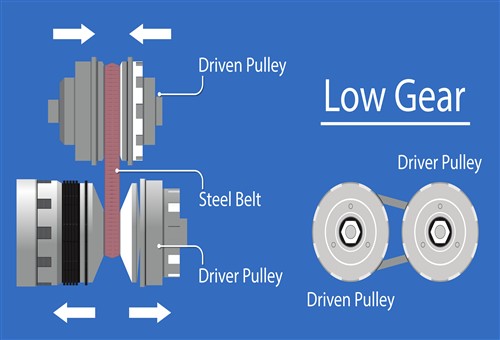

This graphic shows the opposite configuration: the drive pulley's effective diameter is now at its smallest, while the driven pulley's effective diameter is at its biggest, thus producing a ratio that is analogous to first gear in a manual transmission.

So unlike manual and conventional automatic transmissions that have fixed gear ratios, only the lowest and highest ratios in a CVT transmission are fixed, since these are dictated by the minimum and maximum effective diameters of drive and driven pulleys. However, a Nissan CVT transmission (as all other CVT transmissions) can produce an almost limitless number of effective “gear” ratios between high and low “gears” by re-configuring the relative effective diameters of the drive and driven pulleys, which begs this question-

With manual and conventional transmissions, the engine speed and load are the primary indicators that a gear change is required, although actual shift points on automatic transmissions are dictated by the driver-selected operation mode.

Things are different with CVT transmissions though, because “gear shift” strategies are based on the engine’s most economical speed, as opposed to programmed shift points. The principal advantage of this strategy is that the transmission control module can keep the engine running at its most economical speed for much longer than is possible to do with any other type of transmission, thus producing measurable improvements in fuel economy and reduced emissions levels. Here is the short version of how this works-

When a CVT-equipped vehicle moves off from a standing start, the ECU/TCM uses input data from (among other sensors) the throttle position sensor, throttle pedal position sensor, engine speed sensor, vehicle speed sensor, transmission fluid temperature and pressure sensors, to configure the transmissions’ drive and driven pulleys via transmission flow control solenoids so that the transmission is effectively in high gear. As the vehicle’s road speed increases, the ECU/TCM monitors the engine speed and load, but instead of reconfiguring the transmission to perform a “gear shift” at a certain engine speed, the ECU/TCM will maintain the high gear configuration until the engine speed approaches or exceeds the engine’s most economical speed. Deepening on the rate of throttle pedal movement, the ECU/TCM might move the sheaves of the drive and driven pulleys in opposite directions to produce a higher ratio or gear, but this will always occur with reference to the engine's most economical speed, which is that point in the engine's operating range where it produces the most power with the least fuel.

In practice, the operation of a CVT transmission can sometimes produce the disconcerting sensation that the transmission is not responding to throttle inputs, even in variants of CVT transmission and engine management systems that are programmed to interrupt the ignition system momentarily at preprogrammed points to simulate gearshift points, which brings us to-

The rubber band effect

The sometimes-interminable lag between the rising and the engine speed and the vehicle’s road speed has been dubbed "the rubber band effect" because the engine speed can rise somewhat alarmingly without a commensurate increase in the vehicle’s speed.

It is worth remembering that this effect is normal in most Nissan CVT transmissions because a) reconfiguring the transmission sometimes happens in minute increments, and b) all reconfigurations take considerably longer to perform than gear changes in conventional automatic transmissions. Therefore, the rubber band effect is generally not indicative of a fault or defect in the transmission, although in some cases, an excessive lag can be the result of the steel belt in the transmission slipping on one or both pulleys, which can happen for several reasons, which raises t5his question-

Image source: Nissan North America, Inc

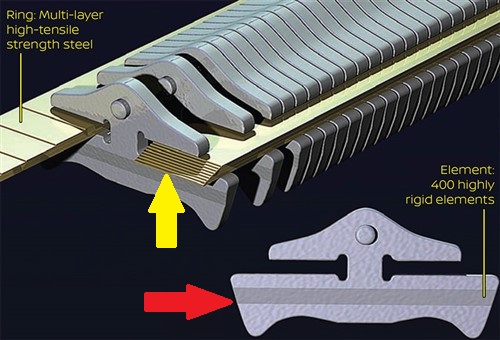

Nissan's CVT dive belts can rightly be described as marvels of modern engineering because they consist entirely of steel components that run over steel pulleys without slipping. Of course, this only happens when the transmission is in good mechanical condition and that it is filled with the correct transmission fluid, but let us consider the above image-

This image shows the construction of a Nissan CVT drive belt; the yellow arrow indicates the number of ultra-high tensile strength steel ring packs, with the number of ring packs determining how much torque the belt can cope with without suffering structural damage. The red arrow indicates one of the 400 steel elements that fit between the ring packs, thus making the belt flexible.

In practical terms, the advantage of this design lies in the fact that as the belt runs over the pulleys, the elements stack up against each other on the belt's return side, thereby forming an almost solid "rod" that pushes the driven pulley, as opposed to the belt dragging the driven pulley. Put differently, this means that instead of the drive pulley placing the belt under tension in the direction of its rotation, the stacked-up elements push against the driven pulley in its direction of rotation, thereby increasing the belt's "grip" on both the drive and driven pulleys.

It is worth noting that although drive belt failures on Nissan CVT transmissions are not entirely unheard of, CVT belt failures are exceedingly rare on transmissions that are-

Be aware, though, that overheating of CVT transmission fluid is a common problem on many Nissan applications that can give rise to several drivability and reliability issues, which leaves us with-

In Part 2 of this two-part article, we will discuss some specific issues and problems you can expect to encounter on Nissan CVTs, as well as some things to look out for when you service a Nissan CVT transmission.