Have you ever wondered what it is that makes the automatic transmissions of today “better” than the automatic transmissions of twenty years ago? We all remember the jolting gearshifts of early automatics, but today, we hardly give the almost seamless gearshifts of modern automatics a second thought. Well, it is usually only when gearshifts that should be seamless become harsh, erratic, or unpredictable that we begin to ponder the possible causes of the problem on behalf of our customers.

So, in what way are modern automatic transmissions different from their older counterparts? How we answer this question largely depends on how we define "different", because the differences between modern and 30-year-old automatics mean different things to different people. For the purposes of this article, however, we will define “different” in terms of control systems, but before we get to specifics, let us answer this question-

In purely mechanical terms, there is very little difference between 30-year-old automatic transmissions and modern transmissions. For one thing, modern transmissions use clutches, planetary gear sets, drive chains, torque converters, pressure pumps, and valve shuttles just like their older counterparts did.

However, over the past few decades, computer-aided design methods have greatly improved the efficiency of torque converters and pressure pumps. Advances in materials science have also improved clutch friction materials, lubricants, and metal finishing/coating processes to reduce friction and mechanical wear between moving parts even more. While all of these advances have greatly improved automatic transmissions, the addition of torque converter lock-up clutches was perhaps the single most noteworthy mechanical improvement to date.

In early automatic transmissions, the trigger signals that initiated gearshifts were changes in the intake manifold vacuum. Although this mode of control worked reasonably well to shift gears, shift points largely depended on the manifold vacuum as a function of engine speed. This feature made early automatic transmissions unpopular since gear shift points could often not be matched to the engine's most economical speed. This translated into the fact that many early automatic models were up to ten percent (or more) less fuel efficient than comparable manual models were.

So what is the point of this lesson in ancient history? Simply this: steady increases in computing power steadily replaced vacuum based-control systems. In fact, modern electronic transmission control systems have more computing power than the desktop computers of just ten years ago had, which is not surprising, given that just the interface between average modern engine management systems and transmission control systems requires several million lines of code to work.

Therefore, the single biggest difference between modern automatic transmissions and their older counterparts involves the precision of the electronic systems that monitor and control every aspect of a modern automatic transmission's operation.

Moreover, very high levels of integration with major systems, including with ADAS systems like stability control, cruise control, and traction control, as well as with throttle control, ABS, and autonomous emergency braking systems, contribute to the bewildering complexity of modern transmission control systems, which begs this question -

Somewhat unsurprisingly, it turns out that hundreds of things can and do go wrong on even the most advanced automatic transmissions. However, even an abbreviated list of failures and malfunctions falls outside the scope of this article, but having said that, one particular category of failures, i.e., shift solenoid performance issues, deserves a special mention, as per the title of this article.

It is perhaps worth mentioning at this point that millions of lines of code, highly sophisticated algorithms, lighting-fast actuators, and advanced lubricants mean nothing if the components that control the actual gear shifts in an automatic transmission don’t work as designed. We might also mention that the electronic control/monitoring system of an automatic transmission represents only one part of the larger control equation.

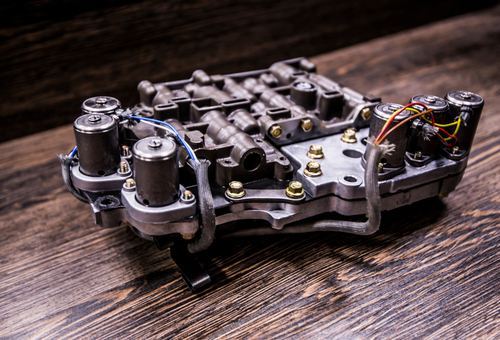

The other part consists of the hydraulic system, which depends on the torque converter, various solenoids, valve shuttles, pressure transducers, pressure switches, pressure regulators, as well as on a pressure pump, electrical wiring, and a sufficient quantity of clean transmission fluid to work as designed.

It is only when both sides of the equation work as designed that we get to experience seamless gearshifts, and while determining on which side of the equation a fault lies is not always easy, an intelligent and informed approach to transmission fault codes usually goes a long way towards making a valid diagnosis. As mentioned elsewhere, this article will focus on one category of faults codes, so let us take a look at-

Despite major differences in the design of automatic transmissions between different manufacturers, all manufacturers are obliged to present generic fault code data in the same way, including generic fault code data relating to shift solenoids. Therefore, while the technical implementation of transmission control and monitoring systems might vary between manufacturers, any particular generic shift solenoid performance code will mean pretty much the same thing on all automatic transmissions.

So what does a shift solenoid performance code mean, exactly? There are various definitions in the technical literature, but for our purposes, such a code merely indicates that one or more shift solenoids are stuck in either the closed or the open position. Note though that some scan tools will display these codes simply as “Solenoid Performance”, without giving any indication of whether the solenoid is stuck in the open or closed position.

NOTE: In these cases, the current symptoms are usually (but not always) good indicators of the status of the stuck solenoid. For instance, if the torque converter clutch is not disengaging, its control solenoid is typically stuck in the closed position. Similarly, if the transmission will not select the next higher forward gear, you can be (fairly) certain that a) the solenoid venting the lower gears' hydraulic circuit is stuck closed, and/or b) that the higher gears' shift solenoid is stuck closed, thus preventing pressurised fluid from acting on that circuit.

So how does a transmission control module “know” if shift solenoid is stuck in a position that it should not be in? To answer this question, we need to look at some of the criteria that transmission control modules generally monitor to determine the status of shift solenoids, but note that while the technical implementation of monitoring strategies vary between manufacturers, all control strategies follow the same general pattern. Here is a generic example-

Shift solenoids control both the pressurisation and venting of hydraulic circuits, either by allowing pressurised fluid to act directly on a clutch pack or through a clutch regulating (pressure) valve. If the fluid acts directly on a clutch pack, the control module will look for verification that the gearshift had occurred by measuring the rotational speed of various rotating components to infer the currently selected gear ratio. On the other hand, if a clutch pack receives pressurised fluid through a regulating valve, the control module will take pressure readings from a pressure switch or a pressure transducer to confirm that the gearshift had occurred.

It is important to bear in mind that no transmission control module in use today can monitor the position of a solenoid shuttle or pintle directly, since these solenoids do not incorporate position sensors. Therefore, control modules use secondary inputs such as fluid pressures taken from specific points or the rotational speed of some components to infer the positions of all solenoids implicated in any given gearshift.

Put differently, the control module "takes the view" that if "X" did not happen, "Y" could not have happened, and as a result, the commanded gearshift could not have occurred. Thus, this roundabout but perfectly logical approach to monitoring the general operation of the transmission is the basis upon which the positions of shift solenoid valves are calculated. This is admittedly an oversimplification of the monitoring process, but the upside is that it reduces the process to its simplest form, which is always a good starting point from a diagnostic perspective, which brings us to-

In the vast majority of instances of shift solenoid performance codes the cause is purely mechanical although in some cases, a solenoid performance code could be accompanied by one or more electrical circuit codes, which must be addressed first. After all, if a solenoid’s electrical control circuit does not work as expected, the solenoid cannot perform its assigned function correctly or efficiently.

Nonetheless, it helps to remember that in the context of transmission shift solenoids, "performance" typically refers to a solenoid's failure to a) retract to a rest position or b) to extend to a commanded position.

NOTE: In some instances, though, a shift solenoid might become stuck between its rest and commanded positions, in which case the control module will detect two gears being selected at the same time, for which there are dedicated trouble codes that will reflect this condition.

In terms of causes of “X” not happening, some issues are more prevalent than others and especially on transmissions with lifetime fills. We need not delve into all the disadvantages of lifetime transmission fills here, beyond saying that unless both the fluid and filter are replaced when shift solenoid performance issues first appear, the fluid will continue to degrade until it eventually turns into a kind of varnish that can (and often does) “weld” solenoid shuttles into their bores.

This is particularly true of shift solenoid shuttles that have pintles on their ends: this type of solenoid is generally not serviceable so if they become stuck, the entire solenoid must be replaced- often as one of an entire set of new solenoids.

Generally speaking, though, shift solenoids fail for only a few reasons- the most common cause being dirty, degraded, or contaminated fluid that forms either sludge and/or corrosion that causes solenoid shuttles to stick or bind in their bores. In many cases, simply replacing transmission fluid will resolve the issue, but once the transmission fluid has turned into varnish, it is often cheaper to replace the entire transmission than attempting to repair the damaged unit. Other common causes of shift solenoid performance issues could include-

Transmission overheating

The most common cause of overheating is the abuse of the transmission, such as using it for towing trailers or boats that exceed the vehicles' rated towing capacity. While it is often difficult to prove owner abuse, the most convincing evidence of abuse is a) the fluid having a “burnt” smell and b) that the transmission fluid has taken on a dark, tarry appearance. Fluid in this condition is unserviceable, and one of its most common effects include-

Low fluid levels

While low fluid levels can set shift solenoid performance codes, it is rare for low fluid levels to set performance codes without additional trouble codes that relate specifically to line and operating pressures also being present.

Mechanical wear of shuttles and bores

While this is usually caused by dirty or degraded fluid, excessive or accelerated mechanical wear is sometimes the result of poor design and/or material choices on the part of the manufacturer.

Regardless of the cause, though, excessive wear can make shuttles bind or stick in their bores. In some cases, pressurised fluid can leak past worn shuttle valves or pintles to enter adjacent hydraulic circuits, which if it happens, can cause other shuttles (that may not be worn) to stick or bind. However, this condition will usually be indicated by the presence of fault codes that relate to multiple gear ratios being selected at the same time, or just as likely, by the presence of codes that indicate a failure to select one or more gears, which brings us to-

It is very important to bear three things in mind whenever you are dealing with shift solenoid issues, these things being-

Transmission fluid has a finite service life

This statement may come across as preaching to the converted, but the fact is that at least half of the automatic transmissions in use today are running on seriously degraded fluid. Like engine oil, transmission fluids consist of base oils to which a package of additives had been added to improve the fluids’ performance and durability. Typical additives include friction modifiers, anti-foaming agents, detergents, and viscosity improvers, and while additives give transmission fluid a reasonably long service life, it does not last forever.

Moreover, given that a) shift solenoid performance issues are almost invariably mechanical in nature, and b), that these codes are by far the most common codes on many automatic transmissions, it would be reasonable to say that most codes in this category are directly caused by degraded and dirty transmission fluid.

Therefore, from a diagnostic perspective, the first step should always be to check and verify the condition of the fluid. This is admittedly not always easy, and especially on units with lifetime fills, but still, the effort involved in obtaining a sample of fluid is both much less expensive than replacing a transmission that could have been fixed by a simple fluid and filter replacement.

Shift solenoids have incredibly difficult lives

While shift solenoids on all automatic transmissions have difficult lives, these solenoids are not all created equal. Constant and large temperature swings, contact with acidic fluid, severe vibration, perpetual cycling between on and off states, and operating in small bores take their collective toll on some valve shuttles much sooner than on others.

While any shift solenoid on almost any transmission can potentially fail prematurely, some transmissions have become notorious for the frequency with which their shift solenoids fail. Thus, if this writer can offer any reader some advice, it would be this; always look for TSBs that address the issue you are seeing before you do anything else.

Many known pattern failures involve specific shift solenoids on specific transmissions, and as a result, there are TSB's that address most, if not all of these known failures. This, too, might come across as preaching to the converted, but if you have not had much exposure to automatic transmissions, finding and implementing recommended repairs, fixes, and remedies will save you hours of testing desired vs. actual pressures and/or current draws, poring over schematics of hydraulic circuits, or decoding wiring diagrams. In short, Google is your friend when you are dealing with automatic transmission issues.

Get as much information as you can

While this is a general rule that applies to all types of diagnostics, it is particularly relevant in the context of automatic transmissions and even more so when you are dealing with intermittent failures or malfunctions.

A good starting point in collecting information is often talking to the customer; because the customer knows his vehicle better than anybody else does. Ideally, you will want to know how the customer experiences the symptom(s), when the problem started, under what conditions the symptom(s) typically appear, and if the problem had been getting worse. As we know, this information often holds invaluable diagnostic clues but if you are new to automatic transmissions, you should also know that scan tools alone will not always help you to find a problem.

To be sure, scan tools can provide important information, but the surest way to define an automatic transmission problem is to drive the vehicle with a multi-channel oscilloscope connected to the transmission. Depending on the number of channels you have available, you can collect real-time data on things like-

This last point is critically important because on most transmissions, something called the “switch voltage” indicates the position of a given shift solenoid when compared to the selected gear ratio.

However, the problem with using waveforms to analyse the operation of an automatic transmission is the fact that learning to interpret the waveforms correctly represents a rather steep learning curve. Then again, we are always learning new things, so with some practice and dedication, you will learn to extract the information you need from these waveforms in no time at all, which leaves us with this-

While we hope that you find the information presented here useful and informative, it should be noted that this article is not intended to be the last word written on diagnosing shift solenoid issues. This article merely provides some background information, meaning that before you dive into automatic transmission diagnostics, you should ideally obtain all relevant technical information, as well as wiring and hydraulic schematics for the affected transmission before you disassemble anything or draw diagnostic conclusions that may or may not be valid.

On the other hand, and absent technical information and schematics, the information provided here should help you to understand the basic principles of how shift solenoids work, and how they affect the efficient operation of automatic transmissions.