The oldest and most experienced among us will no doubt agree that it is becoming tougher to find and fix some kinds of problems on modern cars with each passing year. However, if you are new to the independent car repair industry, there is a high likelihood that as your career progresses, you will often feel like the mechanic in the picture shown here: praying for answers to problems that you do not always fully understand.

Sadly, though, Divine intervention is an exceedingly rare event in the car repair industry. Moreover, the old adage that all cars are essentially the same is not even remotely true and has not been true for a great many years. Therefore, what do you do when you encounter problems and symptoms that not only don’t have any obvious connection, but also several potential solutions, any one of which may or may not resolve the problem?

Much of how you approach a situation like this depends on what you know about the issue, and in this article, we discuss a case involving symptoms on a Chrysler Grand Voyager that had no apparent connection with each other. Before we get to the specifics, though, let us rephrase the title of this article in the following way-

While it is true that the vast majority of young mechanics start their professional careers with a solid grounding in both mechanical and electrical theory, modern professional environments demand more of new entrants than a sound knowledge of the relevant theories.

For instance, it has been this writer’s experience during his long careers as both a working technician and an employer that while much, or even most of auto mechanics can be taught, truly outstanding technicians possess qualities and character traits that cannot be taught.

We could list many such qualities and traits here, but because this article is not intended to be a training manual, we will focus on one such trait that this writer’s resident diagnostician has in abundance- his ability to ask the right questions under high-stress conditions. As a result of his ability, the diagnostician also serves as our resident training officer, and this article focuses on how he once applied this critically important skill when a young technician that had just completed his training at a local Ford dealership started his professional career at our independent workshop.

Before we get to our case study, we must spend a few words on the diagnostician. For one thing, and in the interest of fairness, it must be said he is not perfect and does sometimes get things wrong, but the number of times he was wrong is vanishingly small compared to the thousands of times he was right.

One more thing about him is that while he is a hard taskmaster, one week of working with him is equal to at least a year’s worth of training anywhere else. This is not because he knows more about more cars than (almost) anybody else does; it is because of his no-nonsense approach to diagnostics, which can be encapsulated by the four bullet points below-

If you are an experienced technician, you may hold similar views on diagnostics, and in that sense, the above may come across as preaching to the converted. Nonetheless, if you are just starting your professional career, the above-mentioned sentiments hold invaluable lessons, as we shall see in the case of-

As the young Ford technician’s bad luck would have it, this minivan that belonged to a regular customer, arrived at the workshop on the back of a recovery truck just as the diagnostician was lecturing him (the new mechanic) on the importance of keeping proper records of all repairs to construct his own diagnostic database.

Long story short, though- the customer complained that for the past few days, the engine had been stalling unpredictably both while he was driving around town, and to work and back home on the highway. There was no pattern to the issue since the engine stalled under a wide range of operating conditions, road speeds, and engine loads. The strange thing was, however, that no warning lights have come on at any point during this time, and all the instruments and gauges always seemed to work normally and always registered normal readings. The engine always started after a bit of cranking, which he (the customer) thought might be because he had recently started using fuel of a different brand, so, would we mind taking a look at the problem?

We knew this particular van well, and we were also aware of the high level of care this customer bestowed on his vehicles, so the diagnostician immediately discounted poor servicing or a lack of maintenance as a cause of the stalling issue. Nonetheless, the diagnostician recognized this issue as a teaching opportunity, so he handed the young Ford tech a GM specific scan tool and instructed him to see if he could extract fault codes.

We had a result fairly quickly; the only active stored code was P0480 - “Cooling Fan 1 Control Circuit/Open”. There were no pending codes.

However, the young tech made the mistake of clearing the code, as he put it, in anticipation of the next step, which was to see if he could reproduce the problem during a test drive. This was a mistake, since clearing the code also erased all associated freeze frame data. This was a classic rookie mistake, but (sometimes) being a forgiving soul, the diagnostician did not press the point, which brings us to-

Since the diagnostician did not believe in holding any trainees’ hand, he simply turned the problem over to the young Ford tech by saying-

“You have a problem, a symptom, and a fault code, so now you need to reduce the problem to its simplest form by asking and answering two questions. You need to ask yourself if there is a relationship or connection between the engine stalling and the open circuit in the cooling fan circuit, and if so, you need to explain how a defective fan circuit can cause the engine on this particular vehicle to stall- given that the engine has not overheated. Call me if you get stuck.”

The Ford tech may have had four years of training and a fair bit of practical work experience, but since all of his work experience had been on Ford products, he got stuck very quickly and admitted defeat when the diagnostician checked on his progress. Here is the short version of the ensuing conversation-

Diagnostician: So what did you learn?

Ford tech: Not much, but I think I need to take a test drive to see what happens when the engine stalls.

Diagnostician: How will that help you? The engine stalls under different operating conditions and loads, so you could spend a week driving the vehicle and still not know anything one way or the other.

Ford tech: OK, that makes sense. But can we get a wiring diagram? I’d like to see how this vehicle is wired…

Diagnostician: I can get you all the wiring diagrams you want but in this case, it won't help you in any way. Remember I said, “…this particular vehicle?”

Ford tech: So what’s so special about this particular vehicle? Does it have something other vehicle makes don’t have; something that can make the engine stall if a cooling fan circuit fails?

Diagnostician: Great, now you’re beginning to ask the right questions, which is the most important skill you need to learn if you want to survive in the independent repair industry. Here’s the thing; the only way to diagnose many electrical issues on GM or Chrysler vehicles is to simplify the problem. Forget about complicated diagnostic strategies, or complex tests, and focus on the basic problem, which in this case, is not the engine stalling, but the open circuit in the cooling fan’s wiring.

Ford tech: OK, but are the two issues not connected or related?

Diagnostician: They are, but only in a roundabout way because if some car parts could be evil, most GM and Chrysler vehicles have something that could be called Prime Evil. They have something called a Totally Integrated Power Module, and if you know what it does and how it works, you can fix almost any electrical problem on any GM or Chrysler vehicle simply by replacing this so-called module.

We can exit the conversation at this point.

However, what follows might be helpful and even instructive to those among us who are not familiar with Totally Integrated Power Modules on GM/Chrysler vehicles, which brings us to-

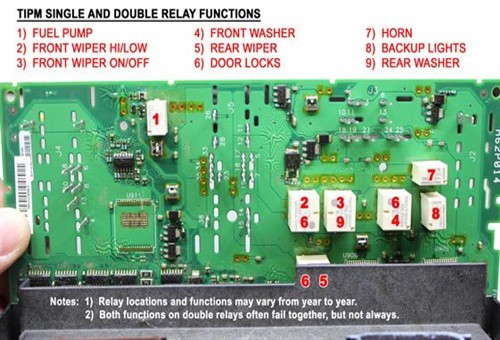

Image source: https://www.verticalvisions.com/pub/media/wysiwyg/TIPM/TIPM_relay_functions1.jpg

While the fuse boxes on these vehicles look just like regular fuse boxes, the fact is that the fuses and relays in GM/Chrysler conceal what is probably one of the most unreliable, badly conceived, and poorly executed pieces of electronic circuitry even perpetrated on both the public and mechanics the world over.

The image shown above shows a typical example of the circuit board under the fuses and relays in a typical Chrysler vehicle, so if you have not seen one before, this is a representative example. What is not shown here, however, are the several microprocessors on the other side of the board that act as preliminary “clearing houses” that check and monitor the validity and integrity of several critical engine and fuel management signals- before passing them on to the ECU proper.

As a practical matter, all or most electrical signals on GM and Chrysler vehicles pass through this circuit board at least once, but in most cases, signals pass through this module both on their way to a control module, and on their way from a control module to a valve, solenoid, actuator, or some other component. If this board were properly designed, passing some signals through it multiple times would not be a problem, but as it turns out, these boards are so failure-prone that most, if not all electrical failures on GM and Chrysler vehicles are directly attributable to design defects in the circuit board.

As a result, wiring diagrams are of limited diagnostic value, since the interactions or the level of “interconnectedness” of circuits in the microprocessors are not known, or shown on any wiring diagram. However, what is known is that on Chrysler Grand Voyagers, the engine’s temperature is monitored by one such microprocessor that verifies signals from one or more coolant temperature sensors before passing the signal to the ECU, which then activates the cooling fans (when required) by supplying a ground path for the cooling fan relay through the Totally Integrated Power Module’s circuit board.

So in the case of this particular Chrysler Grand Voyager, how did the diagnostician know that the Totally Integrated Power Module was the cause of the random engine stalling? Well, apart from the fact that he had fought and won many battles with this module on other Chrysler vehicles, he performed two simple tests- mainly for the benefit of the Ford tech. Here is what he did-

He tested the radiator fans

First, he tried to activate the radiator fan with the bidirectional controls on his GM-specific scan tool, which failed to turn on the fan. Next, he disconnected the fan's electrical connector and connected it directly to a clean power supply with some jumper wires. This made the fan motor start and run at what appeared to be a normal speed.

This test proved that the problem was either in the Totally Integrated Power Module or in the wiring between the module and the fan motor.

He scoped the fan motor relay

Since there was a microprocessor and a normally open relay between the fan’s electrical connector and the ECU that supplies the relay’s ground, the diagnostician did not perform a voltage drop or continuity test on the wiring.

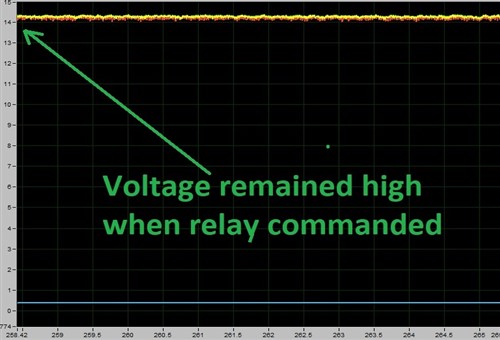

Instead, he spliced his oscilloscope into the fan’s wiring close to the connector and started the van’s engine to let it warm up. He started his scope just before the heat gauge on the dashboard registered “Normal”, but left the scope running until the gauge registered well above “Normal”. This is what he saw-

This waveform stretched over several minutes, and as shown here, the voltage remained high when the relay should have been grounded at least once. Thus, since no communication codes were present on the vehicle, the diagnostician concluded that the ECU was indeed supplying a ground path, but the Totally Integrated Power Module was not executing the ground connection- a conclusion he based on many previous engagements with Totally Integrated Power Modules.

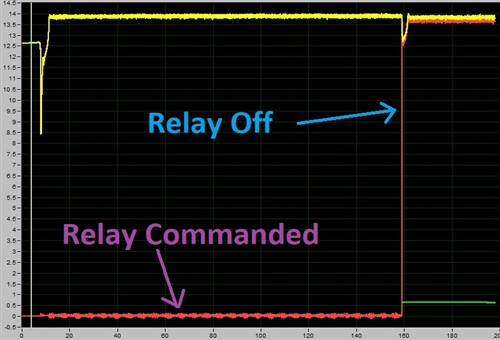

Armed with this diagnosis, we obtained authorization from the customer to replace the hugely expensive Totally Integrated Power Module with a new OEM part. To improve the Ford tech's knowledge of Chrysler electrical issues, the diagnostician scoped the fan relay again two days later after the module had been replaced. This is what he saw-

As shown here, the new Totally Integrated Power Module executed the fan motor relay’s ground connection when the engine reached its specified operating temperature, which brings us to this question-

This is perhaps the most "right" question to ask, but the fact is that nobody can say for sure. In fact, the design and execution of Totally Integrated Power Modules on Chrysler and GM vehicles, and particularly on vehicles from the 2010, 2011, 2012, 2013, and 2014 production years were so problematic that many American car owners and several consumer protection organizations in the US market started a huge class-action lawsuit against GM and Chrysler in 2014 to address the issue. You can read more about this class-action suit here.

The best way to answer the question of exactly how and why a defective Totally Integrated Power Module can affect many electrical systems on Chrysler and GM products is to list some of the known symptoms of defective Modules. Note, though, that while the list below covers a lot of ground, it is almost certainly neither complete nor exhaustive. Nonetheless, it includes the known symptoms of defective Totally Integrated Power Modules that this writer and his technical staff have encountered and verified over the past decade-

We hope that you find the above list of symptoms helpful but bear in mind that official Chrysler sources, such as repair manuals, are silent on these issues. To illustrate this point, consider this section of an official Chrysler repair manual that describes trouble code P0480, the code that was present on our Chrysler Grand Voyager-

Trouble code P0480 Symptom Descriptor:

Probable Causes:

Code Set Conditions:

The Powertrain Control Module (PCM) is requesting the Totally Integrated Power Module (TIPM) to turn the Cooling Fan On and it is not operating

When Monitored and Set Condition:

P0480-COOLING FAN 1 CONTROL CIRCUIT

When Monitored:

With the ignition [is] on. Battery voltage [is] greater than 10 volts.

Set Condition:

An open or shorted circuit is detected in the radiator fan relay control circuit. One Trip Fault

Source: Chrysler USA

It should be noted that it is not the intention of this article to create the impression that all electrical issues on all GM and/or Chrysler vehicles can always be attributed to failures of Totally Integrated Power Modules. In all electrical failures, proper diagnostic procedures must be followed, and all findings must be verified before you replace any control module(s).

Nonetheless, if a seemingly defective component on a Chrysler or GM vehicle works when it is powered directly, or you come across symptoms that can’t be related to each other, you could save yourself a lot of time and trouble simply by blaming the problem on the Totally Integrated Power Module.

The chances that you would be wrong are very small- because sometimes, knowledge about built-in defects on some cars can be a more powerful diagnostic weapon than the ability to formulate a complex diagnostic strategy. As our resident diagnostician always says- “Knowledge is power, but if you can ask the right question at the right time, your knowledge makes you look like a magician.”