We had a conversation with a technician a few weeks ago and the subject of Electronic Stability Control came up. When asked exactly what it was, the response was “Well it’s like 'tricked-up' ABS”

While this may not be 'incorrect', it’s important to understand the difference between ABS, Traction Control Systems and Electronic Stability Control.

ABS and Traction control systems control the vehicle along the longitudinal (front-to-back) axis, while ESC controls the vehicle along the lateral (side-to-side) axis.

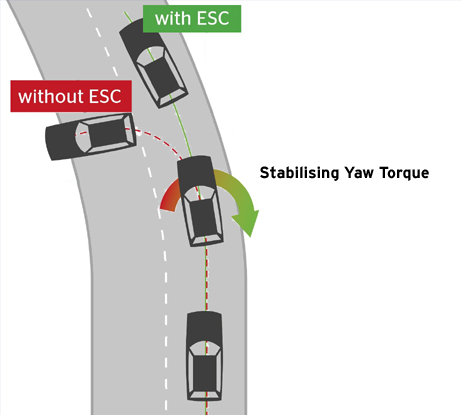

The objective of all electronic stability control systems is to prevent a vehicle side skidding and losing control however it is a system that is often misunderstood.

In this article, we’ll take a look at exactly how electronic stability control (ESC) works as well as some tips for diagnosis.

What is it and why do we need it?

You’re on your way to work in the morning and the road is wet, you’re accelerating around a bend and the rear end starts to step out. Before you’ve had time to back off of the accelerator or touch the brakes your ESC light starts to flash on the instrument cluster, your engine RPM’s drop and you can hear the ABS pump running and solenoids firing. You’re back on track instead of down an embankment thanks to ESC.

Electronic Stability Control goes by many different names; Honda call it ‘Vehicle Stability Assist’, Mitsubishi call it ‘Active Skid and Traction Control (ASTC), Toyota call it ‘Vehicle Stability Control’ (VSC) and Volvo call it ‘Dynamic Stability and Traction Control’ (DSTC)

These are just a few of the names manufacturers use to describe Electronic Stability Control in their vehicles, but regardless of what you call it, it saves lives. Government data has shown over recent years that statistically, vehicles equipped with Electronic Stability Control were involved in approximately 40% less severe collisions that involved loss of control of a vehicle when compared with non-ESC equipped vehicles.

ESC anticipates dangerous situations even before the vehicle goes out of control and is so effective, in fact, that the government mandated ESC on new vehicles built after 2012.

ESC is not a new technology. Developed by BMW, Mercedes-Benz, Bosch and Continental Automotive Systems in the late 1980s, it made its road debut in 1995 on the S-Class Mercedes-Benz.

Other manufactures quickly followed suit and by the mid-2000s most manufacturers offered some form of ESC.

10-15 years down the track there are many vehicles on the road with ESC that have travelled a number of kilometers and as a result we are starting to see component failures.

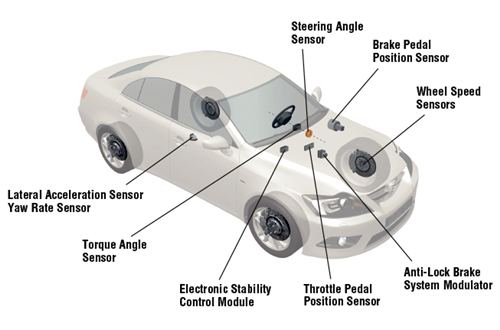

Although systems vary from vehicle to vehicle, the basic components of an ESC system include a control unit that uses algorithms to make the system operate, lateral accelerometers, a steering angle sensor, wheel speed sensor and a yaw rate sensor.

More sophisticated systems may include a brake pressure sensor, longitudinal accelerometers, roll rate accelerometers and throttle position observation.

ESC is a complicated system that links together sensors typically already on the vehicle and makes decisions based on the data they provide. Understanding the basics of these sensors and their correlation to the decisions that the ESC will make is essential to diagnostics and repair.

Wheel Speed Sensors

The wheel speed sensors are an essential part of ESC that must accurately report each of the vehicle’s wheel speeds to the ESC module. The passive type wheel speed sensor uses a magnet and generates an AC current and resulting sine wave. This was the most common kind of wheel speed sensor, but the active wheel speed sensor is more accurate and can measure wheel speed all the way down to a complete stop and can even recognise that wheel’s rotational direction (it is possible to know that the wheel is turning backwards). These features have made the active wheel speed sensor a popular choice for many of today’s vehicles.

Active wheel speed sensors require special testing and usually involves a scan tool. When testing an active wheel speed sensor, it must be carefully back-probed (still connected) during testing and you will be looking for a supply voltage.

This voltage can be 5v to up to 20v depending on the system. Many vehicles use 12 volts or battery voltage, and when testing it is imperative to make sure it’s the same on all four sensors. Because an active wheel speed sensor is a two-wire sensor, the control unit will measure the return signal, so it’s not possible to test for a reference voltage or resistance across the connector terminals. Some BMW’s and Hondas shut off the power supply if the sensor is disconnected, but it will come back if the sensor is hooked up and the key cycled.

Accelerometers

Yaw rate and lateral acceleration sensors are fancy names for G sensors or accelerometers. We have the same devices in our mobile phones that are used for various apps. The purpose is to sense a variation in direction, either left or right or side-to-side. The yaw rate sensor will measure the rotation rate of the vehicle and determines how far ‘off-axis’ the vehicle is tilting or rolling in a turn. The yaw rate sensor is usually mounted low and in the center of the vehicle (often under the center console to be as close to the vehicle’s center of gravity as possible) so that its measurement is more precise.

The lateral acceleration sensor measures the rate of change in side-to-side movement to calculate the vehicle’s actual position in the turn.

In many cases the lateral and yaw rate sensors are incorporated into one single unit or combined as a sensor cluster. These sensors can be directly wired to the ESC controller or on the CAN-bus system, sharing information with other controllers.

Transverse and roll-rate sensors can also be incorporated into the system to help detect and prevent vehicle rollovers. These sensors can also be an all-in-one design or they can be mounted individually on the chassis.

Most of these sensors can only be tested with a scan tool, but like a steering angle sensor you can test for communication activity on the output line with a meter or scope.

Steering Angle Sensors

The steering angle sensor (SAS) reports the position of the steering wheel and how fast the steering wheel is being turned. The ESC module needs to know this information to compare it with yaw and lateral accelerometer info to decide what the driver really intended to do.

There are analog, digital and controller area network (CAN) designed SAS sensors with each containing a cluster of sensors for redundancy, precision and safety (much like in an electronic accelerator pedal position sensor).

An analog SAS will have a power (5v reference), a ground, and signal outputs. Normal straight-ahead steering wheel position scanner values or back probing the connector will show 2.8V on one sensor and 0.4V on the other.

The values should not match and the values may go positive or negative as the wheel is turned.

The digital SAS or contactless sensors will use either a Hall Effect sensor or an optical sensor to produce a digital square wave output that will change frequency as the steering wheel is turned.

The CAN-bus SAS can be directly wired to the ESC controller or the information created by the SAS can be shared along the CAN network of the vehicle, and used by other modules such as directional headlights.

This type is diagnosed using a scan tool. It is only possible to see if the SAS is communicating by checking the voltage output on the CAN wire, but you have no idea what is being communicated.

Control Units

The controller for the Electronic Stability Program can be either a separate self-contained unit as shown above or integrated into another controller such as an ABS module and linked via the CAN system for continuously comparing the information from the SAS input, Wheel Speed sensors and accelerometer sensors to determine if the vehicle is reacting the way the driver wants or expects it to. If the vehicle isn’t reacting that way (such as in a side-skid condition) the ESC will make the needed corrections to get the vehicle back to the direction the driver intended if it isn’t.

Using wheel speed sensor data, the ESC controller is looking to see if the vehicle is under-steering (the front wheels will be turning slower than the rear wheels) or over-steering (the front wheels turn faster than the rear wheels) compared to the inputs from the driver.

When this wheel speed sensor data is combined with the yaw sensor data and SAS inputs, the ESC will make calculations and start applying wheel brakes to correct the situation. This brake application could be a single wheel or multiple wheels, depending on what the ESC module feels is the best response using the available data.

If the vehicle is under-steering on a left turn, it may only apply the left-side brakes to assist in a left rotation. The opposite happens if the vehicle is over steering or fish-tailing on a left-hand turn. It will only apply the right or outside brakes to compensate and allow the driver to regain control. If the situation cannot be corrected using the brakes alone, the ESC may also cut the throttle, retard ignition timing, shut off injectors and even change transmission settings to intervene, all attempting to allow the driver to regain control.

When this skid condition is happening, the driver may be alerted with a flashing ESC light. The driver may also hear the ABS functioning, and may notice a decrease in power until the ESC has decided to return control.

Other features can be added to the base ESC programs to improve other stability issues that normal drivers can experience.

Some systems can control trailer sway by detecting the yaw induced into the pulling vehicle by the trailer. This system will automatically apply the needed individual brakes on the tow vehicle to get the trailer and tow vehicle back in line. This is a very difficult strategy to calculate and program effective algorithms for

Corner braking can be incorporated into the ESC system, to improve the vehicle’s stability if the driver brakes during a slippery turn or where traction is different from right to left.

Because an uneven braking force will result at the wheels due to a weight shift to the outside of the turn, the ESC unit will observe the front wheel speed sensor differences and can pulsate the braking on the outside wheels to create an equal braking force on all four wheels.

Stopping on a road surface that has a friction difference between left and right sides of the vehicle may need some ABS activation to provide balanced braking, but the driver will usually need to provide some form of steering input to keep the vehicle going straight.

In this situation, the ESC unit may command some steering input from the electric power steering if equipped even before the driver has a change to recognise the need to do so.

Repair

An up-to-date information system and good scan tool is a must in diagnosing an ESC system. Most ESC systems will provide trouble codes that will lead a tech into the area of concern, commonly involving wheel speed sensors, yaw or steering angle sensor issues. But even a misfire may turn on an ESC light due to the fact the ESC needs the engine to be running properly for it to function as designed. In this instance you will often see a relative fault code on the ESC control unit as well as the engine/powertrain control unit, therefore full system scans are always recommended when carrying out any diagnostics.

Wheel speed sensor diagnostics and their replacement is going to be vehicle dependent. Many wheel speed sensors are now incorporated in the wheel hub design and are not available separately. Understanding the type of wheel speed sensor is critical for proper diagnostics. The use of a scan tool is going to be typical and most good scan tools provide the ABS information needed for diagnosis.

Most Steering Angle Sensors require some sort of resetting or calibration after replacement, an alignment, steering wheel removal or service or whenever an ESC component is replaced, but don’t be surprised if you must perform this even after a battery replacement. Many new alignment racks will now properly re-calibrate the Steering Angle Sensor after an alignment using proprietary software through the diagnostic port.

Many newer Steering Angle Sensors self-calibrate by requiring you to turn the steering wheel slowly lock to lock, and driving the vehicle over a certain speed and distance and will turn off the service light after an appropriate drive cycle. But frequently a scanner is going to be required.

Almost all G sensors (yaw, lateral, or roll rate) will need to be zeroed or initialized after replacement, to allow the ESC to recognize their neutral position. This usually requires the vehicle to be on a flat, level surface and generally in an unloaded state, with the wheels pointed forward. Yet again, a scanner will be required and the proper information on the procedure.

Attention to fastener torque, proper sensor orientation and location mounting is imperative for proper operation of these sensors.

If the ESC unit is going to be replaced, a factory scan tool may be required to install the flash or programming, but some are simple and only need to be initialised.

Not a magic wand

It’s important to remember that an ESC system has limits. Tire tread, tire pressure, steering components, proper brake components and suspension parts all must be inspected and verified to be in working order. Parts must be replaced properly and initialised to function correctly.

ESC was not designed to allow for faster cornering speeds or aggressive driving on slippery roads. It was designed to increase safety and vehicle control.

But this system isn’t fool-proof. It can’t overcome the simple laws of physics, and if the base systems aren’t functioning at the appropriate level, this system won’t be able to work as designed.