Image source: Wikimedia Commons (Public Domain)

This image shows a 2004 Ford F150 truck with a 6.0L Powerstroke turbo diesel engine. If you are not an expert diesel mechanic, you may not know that the sight of this vehicle/engine combination often induces feelings of fear, despair, trepidation, wild panic, and serious self-doubt in even experienced mechanics and technicians- simply because they never know what they will be dealing with when this combination rolls into their bays.

We are not saying this to bash this Navistar-manufactured engine unnecessarily. However, the fact is that in the experience of many mechanics and Ford fans, the 6.0L Powerstroke engine is the worst engine Ford has ever installed in any of their products- as our customer discovered recently when his newly- acquired (but previously owned) F150 suddenly developed the dreaded “Long-Crank, No Start” problem. We discuss this problem in some detail in this article, but before we get to specifics, let us state-

Ford had stopped using the 6.0L Powerstroke engine Super Duty trucks in 2007 when it was replaced by the somewhat more reliable 6.4L and 6.7L versions of the original 6.0L engine. Therefore, this writer was somewhat taken aback when he discovered that this particular truck featured what must have been one of the very few remaining non-bullet-proofed* 6.0L Powerstroke engines still in existence.

*This engine had the standard-issue oil cooler on it, so we knew the engine had not been bulletproofed, which is a rather expensive process that we will discuss in a follow-up article.

This writer was taken aback, even more, when it turned out that the vehicle belonged to a regular customer of his who believed that Duramax and Cummins diesel engines were the only engines worth owning. Therefore, it came as a bit of surprise when this customer turned up in a Ford truck with an engine that was widely acknowledged to be problematic, to say the least.

Long story short, though; the customer bought the almost-pristine truck from a deceased estate for a small fraction of its retail value, based purely on the fact that it had less than 30 000 km on the clock. Not having any experience with Ford products, the customer believed that not much could possibly be wrong with it since it drove well enough for the two weeks that had owned it. Turned out that the owner was wrong about that because subsequent investigations showed that the truck had only 30 000 km on it because that was when the high-pressure oil pump failed catastrophically.

Although the truck had been repaired by a Ford dealership after it broke down, the then owner refused to drive the truck ever again and placed it into storage to be preserved until his youngest grandson was old enough to inherit it. However, the previous owner died unexpectedly in 2009, and since the grandson did not want the truck it was sold on auction, where the current owner bought it.

None of this is really relevant to the story, except for the fact that the vehicle was in exceptionally good condition. The Ford dealership that repaired the truck more than 10 years ago was contracted to collect the vehicle and to get it running again. According to the current owner, this took less than a day; the dealership removed the preserving oil from the cylinders and crankcase, replaced the oil filter and both fuel filters, and filled the engine with new oil.

Then they replaced the batteries and the tyres, before filling the tank with fresh fuel. Somewhat surprisingly, (according to the owner) the engine started right up after only a few second’s cranking, and what little smoke there was cleared up after a few minutes.

The rest was easy; the dealership tech removed the wheels to check on the brakes, replaced the brake fluid, bled the system, and ran a diagnostic scan on the whole vehicle. There were no fault codes stored, nor were any pending codes present. Thus, from the customer's perspective, his newly acquired F150 was in perfect working condition until the day before, when it would not start as easily as it used to.

According to the customer, the engine would only start after an extended period of cranking when the truck had been parked for even a few minutes. Then, when it did start, it ran extremely roughly for a while, and if the engine were cold, it would not idle until it had warmed up a bit.

The funny thing was, though, if he shut the engine down immediately after starting, it would start again immediately, and it would both idle and run fine until it was again parked for a few minutes. Thus, would we mind taking a look at the problem, and at the glow plugs, in particular, since his Duramax-engined vehicles do much the same thing when the glow plugs get old?

Having fought several protracted battles with 6.0L Powerstroke engines before, we were not particularly keen “to have a look at the problem”, mainly because we knew that this common problem was hardly ever related to glow plugs. In fact, this problem almost invariably involved-

Nonetheless, since this customer had spent a lot of money with us over many years, we saw no advantage in not making him aware of the potential cost of each possible cause of his problems. This did not seem to worry him in the least, so we agreed to “have a look”. Here is-

The resident diagnostician, (whom we have featured in these pages before) thought it might be a good idea to let the truck sit overnight, so we pushed into an empty bay, and closed up shop for the night.

First thing the next morning, the diagnostician connected his Ford-specific scan tool to the truck's DLC, and despite a diligent search, he failed to find any trouble codes- neither active nor pending. This was not necessarily a problem so he tried to start the engine, but all that happened was that he ran the batteries down and nearly fried the starter motor.

After changing the batteries and cooling down the starter motor by dumping a bucket of cold water over it, we eventually managed to get the engine started. It ran extremely roughly and would not idle, just as the customer said, but undeterred, the diagnostician kept the engine running until the idling smoothed out without throttle inputs.

Seeing his chance, the diagnostician reconnected his scan tool, but this time, he found code P0299 - “Turbocharger Under boost Condition”, and P0401 – “EGR Insufficient Flow Detected”, both of which kind of made sense at the time, so we disregarded these codes as primary causes of the problem. However, when the diagnostician turned off the engine, a “Water In Fuel” message appeared on the dashboard.

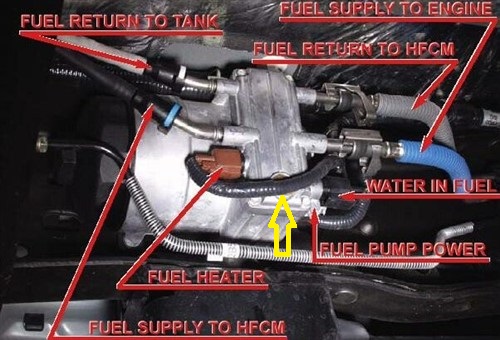

The lack of fault codes on 6.0L Powerstroke engines is almost a diagnostic clue in itself, so we decided to start the diagnostic process by checking the electric lift pump’s power draw and output. It was also at this time that we became aware of the strong smell of diesel fuel, which brings us to a short lesson in the fuel system of the 6.0L Powerstroke engine. Here is-

This image shows the low-pressure fuel system “module” as seen from below, with the yellow arrow indicating the location of the water drain plug, which incidentally, does not play a role in this tale.

What does play a role is a sensor that is marked “WATER IN FUEL”, which clearly showed evidence of fuel leaking from it. For reasons that were never clear to anybody, Ford chose to make this a press-fit sensor, in the sense that it does not screw into the manifold that houses all the other sensors. Therefore, if you want to remove this sensor, you simply rotate it 90 degrees anti-clockwise*and then pull it from the manifold hoping not to destroy the Viton O-ring seal in the process.

*Starting early in 2005, Ford changed this sensor to a threaded design.

In this case, by merely tugging gently on the connector, the diagnostician pulled the sensor from the manifold, meaning that the dealership mechanic who had flushed the fuel system did not lock the sensor into place, which in his defence, is an easy mistake to make seeing that the sensor is not threaded.

We never did discover why the pressure in the manifold did not push the sensor out of its seat altogether, but that is beside the point- the point was that the leaking sensor prevented sufficient pressure from building up in the fuel system, which caused the long cranking times. It also explained why the engine started right up after shutting it down- there was sufficient residual pressure in the system immediately after shutting the engine down- for a few seconds, anyway.

Another point worth making is that the FICM (Fuel Injection Control Module) is extremely sensitive to abnormally low fuel pressures. This is probably why Ford designed the pump to run for at least 20 seconds after the ignition is switched “ON”; it gave the pump sufficient time to build enough pressure to overcome the effects of small leaks, low pump rotation speeds, and/or issues with the fuel pressure regulator.

Anyhow, assuming-

- a 6.0L Powerstroke engine will typically start and run with no trouble at all.

The trick is, of course, to have all of the five points listed above in place at the same time, which, it must be said, is not always easy on a 6.0L Ford Powerstroke engine. Thus, since the press-fit version of the Water in Fuel sensor was no longer available, we had to replace the manifold on the fuel module to accommodate a threaded sensor. These parts took four days to arrive and another several hours to install, but it did resolve the fuel leak, and by extension, the excessive cranking times. Well, it did resolve the excessive cranking issue for a while, at least. Here is-

We stated elsewhere that we had fought protracted battles with 6.0L Powerstroke engines before, so we thought we got off lightly this time when the engine started every time at about 30-minute intervals. We also could not find any evidence of other fuel leaks, so the diagnostician cleared the fault codes he had found earlier, and decided to take the truck for an extended test drive, which ended about 20 km from the workshop when the engine suddenly died.

When the diagnostician called the workshop with this bad news, he also said that the truck performed extremely well; there were no misfires, turbo lag was acceptable and throttle responses were good, and that no warning lights appeared when the engine died like it was switched off. It just died without warning; there were no warning lights on the dashboard now, and since it was an automatic and could not be towed, could we send a recovery truck to fetch both him and the vehicle?

Back at the workshop, we nearly fried the starter motor again, but this time, the truck would not start at all. As a first step, we checked that there was fuel in the tank despite the fuel gauge saying that it was nearly full. Banging on the tank showed that there was plenty of fuel in the tank.

Next, we checked the fuel module for (new) leaks but found none. However, switching the ignition on, we could hear the pump running, but it was clearly not building sufficient pressure to start the engine. On (almost) any other vehicle, it would have been a simple matter to check the fuel pump’s output pressure, but again for reasons that are not clear, Ford chose to place the test port* in such a position that is it all but inaccessible.

*One aftermarket supplier did develop a cap for the secondary fuel filter housing that incorporated a test port, which was supposed to make it easier to take fuel pressure readings. While the idea was good, the execution was not; in fact, this test port was so prone to failure/leaks that it was all but unusable- not to mention dangerous when fuel leaking from this test port started spraying over the hot engine.

In practice, the fuel pump delivered fuel to the secondary fuel filter, which incorporated a bypass valve that redirected excess fuel pressure back to a point in the pump’s inlet. “Excess fuel pressure” on the 6.0L engine was anything more than 3.1 Bars above nominal pressure, and if the bypass valve worked correctly (which it often did not), the fuel pump would draw between 5 and 6 amps.

In the days when un-bullet-proofed 6.0L Powerstroke engines were still plentiful, this bit of knowledge was the basis of a very handy workaround. Instead of testing the fuel pressure output of the pump through a mostly inaccessible port, one could measure the current draw of the pump on its wiring, which was routed through the kick panel on the passenger side.

Provided the pump was in a reasonably good condition, its current draw was a reasonably good indicator of its pressure output. In this case, however, the pump drew less than 2 amps, which meant that the bypass valve had almost certainly failed and that it was redirecting most of the pressure in the system back towards the pump's inlet. It was effectively causing the fuel in the system** to circulate through the system instead of feeding* the fuel injectors.

* If you are not an expert in Powerstroke engines, you may not know that the 6.0L version did not have a high-pressure fuel injection pump. Instead, this engine used highly pressurised engine oil to pressurise the fuel in the injectors, which produced exceptionally small fuel droplets. Nonetheless, this high-pressure oil system had many issues of its own, and diagnosing this system was time-consuming, challenging, and generally, not for the faint of heart.

NOTE: The exceptionally fine fuel atomization this design produced was the primary reason why Ford was able to meet and exceed the 2004 iteration of EPA-mandated exhaust emission regulations a full year early. It also explained why the 6.0L engine made more power than its predecessor, the 7.3L Powerstroke engine.

** This part of the fuel system effectively accounted for more than 95 per cent of the entire fuel system. As a practical matter, the only parts of the fuel system that could properly be termed “high-pressure” were located inside the fuel injectors, between the intensifier pistons and the actual injection orifices.

We can skip over the details of what it takes to replace this bypass valve, beyond saying that we did replace it with Ford’s upgraded “blue spring” unit, which provided and maintained a meaningful increase in effective fuel pressure. In theory, this should have resolved the fuel supply issues on this engine, but as it turned out, the sudden lack of fuel pressure that resulted from the failure of the pressure bypass valve caused severe, and very expensive fuel injector failures that we will discuss in the next article, which leaves us with just-

As we stated at the beginning of this article, it is not our intention to bash or denigrate Ford’s 6.0L Powerstroke engine unnecessarily, even though in its standard form, it is not nearly on the same level of reliability as even the worst Cummins or Duramax engines.

However, the key here is the words “standard form”, because, in this form, this engine required significantly more care and maintenance than any of its immediate successors ever did. But then again, in its bulletproofed form, this engine is still hugely popular in drag racing and other forms of motorsport and car culture all over the world today.

Thus, in the next article, we will not only continue our tale of trials and tribulations with this engine in its standard form but also what it meant to bullet-proof a 6.0L Powerstroke engine.