In Part 1 of this series of articles, we recount the tale of our battle with a 2004 Ford F150 truck with a 6.0L Powerstroke engine that had been in storage for more than ten years. If you missed the previous article, the gist of the story is this- a regular customer of ours had bought a 2004 Ford F150 truck that had been in proper storage for more than a decade. A Ford dealership had gotten it running again, but after two weeks of use, the truck suddenly developed the dreaded “Long crank No-start” condition that used to be so familiar to owners of 6.0L Powerstroke engines.

We discovered that the original problem was caused by a leaking sensor in the fuel pump module. While fixing this resolved the “Long crank, No-start” problem, a new problem arose soon after. During an extended test drive we undertook to verify that the original problem had been resolved, the fuel pressure regulator failed catastrophically, which, as might be expected on a 6.0L Powerstroke engine, caused several fuel injectors to fail. To understand how this happened, we need to understand-

Image source: https://www.drivingline.com/articles/power-stroke-history-lesson-2-60l/

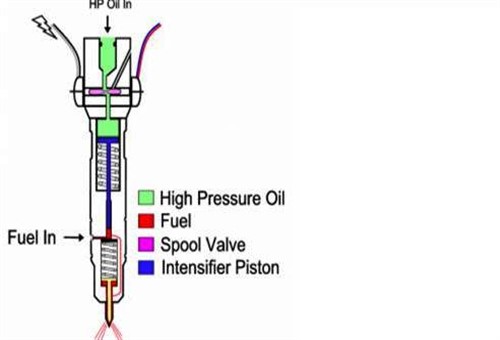

This image shows an example of a fuel injector as used in 6.0L Powerstroke engines, and in case you were wondering, the abbreviation above stands for Hydraulically Actuated Electronically Controlled. The system was made by Siemens.

Let us look at this injector in some detail-

As a practical matter, this injector and its manner of operation obviate the need for a high-pressure injection pump. Let us consider the image below to see how this works in practice-

Image source: https://s3.amazonaws.com/assets.knowyourparts.com/app/uploads/2016/06/fuel-in-300x287.png

The accompanying legend should be self-explanatory, but we need to look at two points because these points explain why some injectors on the truck we were working on failed.

The high-pressure oil (shown here in green) derives from a high-pressure, engine-driven oil pump that delivers oil to each injector via dedicated lines. If the oil pump works as expected, it will deliver a minimum allowable pressure of 34.5 bars; below this pressure, the injector cannot be opened.

Anyhow, assuming that the pump delivers a minimum pressure of 34.5 bars (but up to as much as 248 bars), the oil passes through the valve mechanism between the two solenoids, to enter a so-called intensifier chamber, whose diameter is seven times bigger than the passage that delivers the oil to the chamber. Assuming that there is sufficient fuel pressure to fill the fuel chamber and that the FCIM (Fuel Injection Control Module) works as expected, the 7:1 ratio* multiplies the effective oil pressure by seven.

* The ratio between the diameter of the entry passage and the diameter of the intensifier piston/chamber.

Thus if we assume an entry pressure of 34.5 bars, the effective injection pressure increases to 241.5 bars, which then acts against the tension of two finely calibrated springs to lift the injector needle off its seat. However, the smooth and effective operation of this system depends on two requirements, these things being-

Put differently, this means that the combination of spring tension and the incompressibility of both the oil and the fuel in the injector work together to limit the travel of all the moving parts in the injector to their design parameters.

In the case of our F150 truck, the sudden disappearance of fuel pressure happened too fast for the oil control system to prevent highly pressurized oil from slamming the intensifier pistons into the injector needles. In this case, there was no fuel in the injectors to counteract the force of the inrushing oil, and the result was that the injector needles of four injectors fractured under the impact with the intensifier pistons.

Of course, we only discovered this when the truck would not start after we had replaced the fuel pressure regulator. The same kinds of failures occur when the check valves in the fuel galleries fail: fuel drains from the engine and when the engine cranks with no fuel in the galleries, there is no fuel available (in the injectors) to counteract the force of the high-pressure oil rushing into the injectors.

While these kinds of injector failures on 6.0L Powerstroke engines were not exactly common, they were at the same time, also not exactly uncommon. It was far more likely for the snap-in fittings on the oil feed pipes to the injectors to fail, but this was but a small consolation to the customer when we told him we now had to replace all the injectors as a hugely expensive set. As a point of interest, the set of injectors cost almost as much as the customer had paid for the truck, but as he rather stoically pointed out, the truck was worth nothing if it was not running.

It was during the negotiating process of working out a suitable labour charge to replace the injectors that the customer asked a rather strange question. Not having owned Ford products before, we would have thought that the customer would have done at least some research on this truck before buying it, but here is what he asked-

It turned out that the customer had indeed been doing some research, which mostly consisted of asking owners of non-Ford products what they thought of the 6.0L engine. According to his (no doubt, biased) sources, the long and the short of his research was that the 6.0L Powerstroke engine was by far the worst engine any car manufacturer had ever perpetrated on the car-buying public, and the fact that it was in production for only four years was eloquent proof of that.

Now, the diagnostician could not be accused of being a Ford fan, and although he had been in the proverbial front lines during our previous encounters with 6.0L Powerstroke engines, he gave a well-balanced response. There was, he said, a lot of truth in the stories about these engines being unreliable, but at the same time, nothing is ever as white and black as many of these stories appear to be.

For instance, (as we told the customer), 6.0L Powerstroke engines were indeed known to blow head gaskets for no apparent reason. It is also true that these engines suffered premature turbocharger failures, that they experienced oil cooler issues, and that they had more EGR issues than arguably any other engine known to humanity. It was also true that the fuel injection control module on 6.0L Powerstroke engines failed with distressing regularity.

We also told him that all of these issues had been addressed successfully, albeit not by Ford, who had terminated their agreement with Navistar, the actual manufacturer of this engine when consumer complaints about the engine's unreliability issues reached a fever pitch. This legal battle aside though, many aftermarket parts developers had begun to develop parts and components to improve the problematic parts even while the engine was still in production and as it turned out, these modifications eliminated and resolved all of the 6.0L Powerstroke engine’s reliability issues.

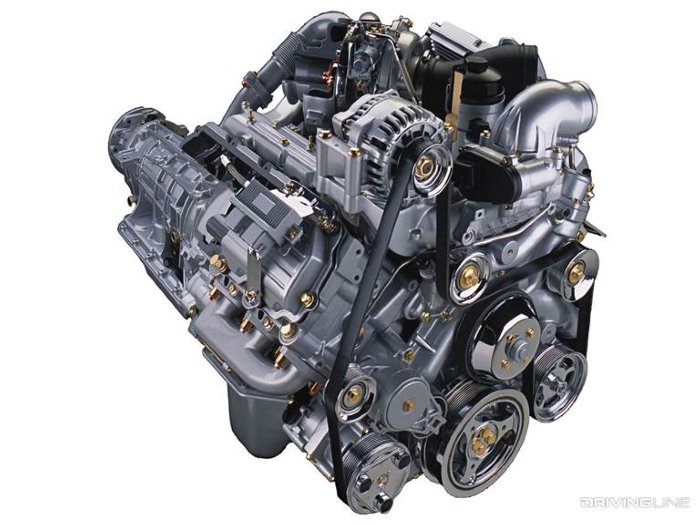

In the vernacular, the process of eliminating the engine’s reliability issues is known as “bulletproofing”, and it involved replacing major engine components. However, since the original “Long crank – No-start” problem this writer was invited to consult on was now resolved, the owner of the truck invited him again to oversee the bulletproofing process, provided the current owners of the workshop had no problem with it. They did not, so here are the details of-

Since bulletproofing this engine is rather expensive, it takes an above-average amount of skill to up-sell the process, but in this case, this writer was not involved with that. However, this writer was involved with the finer details of the execution of the process, so let us start at the beginning, which is to-

This image shows the location of the oil cooler in the valley between the two cylinder banks. The problem with this oil cooler is that while it works reasonably well, it only does so for about 70 000 km before the extremely small passages (that the engine coolant flows through) become clogged up with casting sand, sludge, and other solid particulate contaminants that circulate through the engine cooling system.

Thus, when the cooler becomes clogged, the engine oil's temperature reaches unacceptable levels. This is not only bad for the oil itself- but it is also bad for the high-pressure oil pump that operates the fuel injectors because when the oil gets very hot, the high-pressure oil pump and the injectors develop significant internal leaks. As might be expected, this has serious consequences for the operation of the fuel injection system.

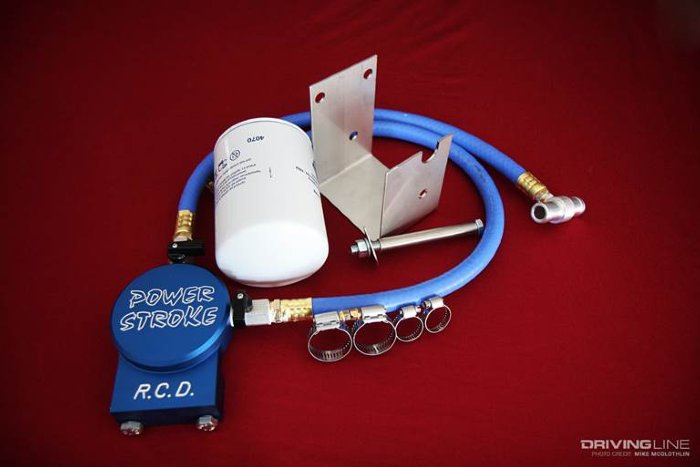

In practice, upgraded oil coolers not only have larger engine coolant passages that generally do not get clogged up, but most upgraded oil coolers also come with-

An engine coolant filter

Although the primary problem of solid contaminants in the cooling system of 6.0L Powerstroke engines was never resolved, the kit shown above does the next best thing, which is to filter out solid particles in the engine coolant before they can become lodged in the oil cooler.

There are several designs of this filter kit available and all seem to work well, but best results are obtained when any design is used with filters that have two-micron (or smaller) ratings. Fuel filters generally work well for this application, but the trick of getting the most out of this addition is to replace the filter every time the actual fuel filters are replaced.

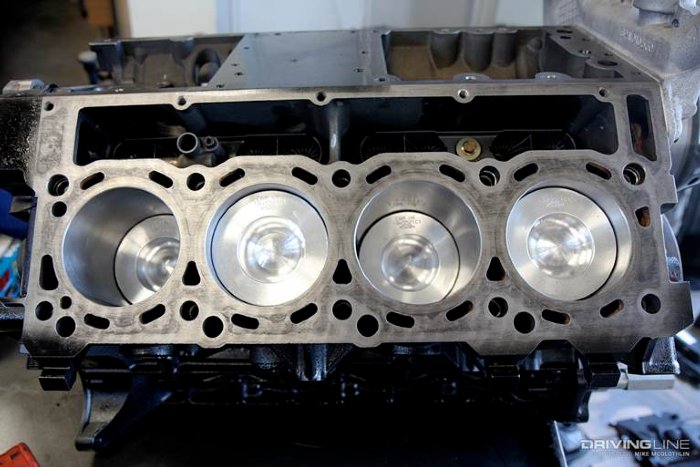

If all the unreliability issues of standard 6.0L Powerstroke engines were equal, then blown cylinder head gaskets will no doubt be the first among equals, simply because of poor design choices on the part of the engineers who had designed the engine.

As shown above, each cylinder head is bolted down with only ten 14mm stretch-to-yield bolts that did not need a particular reason to fail. Anyhow, the problem should be clear; the bolts were not strong enough, there were too few of them, and the 18:1 compression ratio of this engine was just too high to keep the heads bolted down past about 50 000km or so. In practice, even marginal overheating caused the bolts to fail, as even the mildest of mild performance tunes, such as even minor exhaust upgrades.

Nonetheless, aftermarket tuners discovered that replacing the cylinder head bolts with high-tensile studs, nuts, and large load-bearing steel washers that spread the clamping force over a greater area, offered a definitive solution to the issue of incessantly blowing cylinder head gaskets. However, the secret of the success of this remedy is to use studs that screw all the way down into the threaded holes in the engine block, which the OEM bolts did not.

Image source: https://cdn.drivingline.com/media/2310883/012-power-stroke-egr-cooler.jpg?quality=70&mode=pad©metadata=true&w=768

This image shows an example of an upgraded EGR tube. In this case, the tube has vastly improved coolant flow characteristics as compared to the OEM part.

While the original OEM tube could reduce the temperature of the exhaust gas flowing through it by as much as 350 to 370 degrees Celsius over the length of the tube, which was about 30cm, it could do so for only about 30 000km of use before its coolant passages started clogging up.

As soon as this started happening, the hot exhaust gas started precipitating soot and carbon onto the walls of the tube, which soon built up to levels that prevented EGR flow from happening at all. However, before the OEM tube failed completely, the increasing build-up of soot and carbon also started happening in the EGR valve, meaning that neither the EGR feed tube nor the EGR valve itself lasted beyond about 40 000Km or so.

It seems highly unlikely that very many 6.0L Powerstroke engines will still have their original Garret GT3788VA variable geometry turbochargers. While these turbochargers worked well when they were new, and provided near-instantaneous throttle responses, the unison rings that moved the vanes on the turbine wheels seldom worked for more than about 20 000 km or so.

The problem with these turbochargers was two-fold; poor cooling caused corrosion and/or carbon build-up on the unison ring, which caused the vanes to bind or stick in one position, or caused the vanes to move too slowly, which seriously increased turbo lag. The other problem involved a poorly designed 10-vane turbine wheel, which created an ear-piercing screaming sound at high speeds.

Revised versions of this turbocharger included improvements in the vane actuating mechanism and a redesigned 13-blade turbine wheel that eliminated the annoying screaming sound at high engine speeds. As per the heading above, replace the turbocharger as required.

One other major failure point on 6.0L Powerstroke engines was their Fuel injection Control Modules.

For reasons that have never been clear to anyone, Ford engineers chose to bolt the module to the side of one tappet (valve) cover, where it was subjected to severe temperature swings and harmful engine vibrations. Speculating why Ford chose to place this crucially important module directly on the engine is pointless; the better thing to do is to find a location off of the engine to mount the module. This is the most reliable way to prevent failures of the circuit board and internal components.

It is also important to note the 6.0L Powerstroke fuel injection control modules are sensitive to low system voltages, which tend to damage driver circuits.

This procedure is crucially important, not only after a bulletproofing process but after all repairs on the fuel and/or high-pressure oil systems that could conceivably have introduced air into either system.

These procedures are easy to perform. In the case of the high-pressure oil system, use the starter connections provided in the engine compartment to crank the engine for 60 seconds. This allows high-pressure oil to circulate through all of the injectors and other components without starting the engine. Note that if the engine starts before purging air from the oil system, the resulting oscillating pressure waves in the system will destroy the filter screen in the injection pressure regulator (IPR), and fragments of this screen always end up in one or more fuel injectors.

Bleeding the fuel system is simply a matter of allowing the fuel pump to run (KOEO) through several 20-second cycles until the PCM switches it off. Doing this allows the pump to fill and prime the entire fuel system, including the fuel galleries in the engine; not doing this will almost certainly cause one or more injectors to fail because of a lack of fuel to cushion the effect of high-pressure oil rushing into the injectors, which leaves us with this-

For some people, doing all of the above to achieve a high level of reliability on an engine that should perhaps have come with a reasonable level of reliability included in its price, may seem like an absurd thing to do. Given the eye-watering price of this procedure, some people may be right about that, too.

However, the upside is that bulletproofing a 6.0L Powerstroke engine remains the easiest and most cost-effective way of building a powerful yet relatively light and compact V8 diesel engine that is both reliable, and virtually indestructible. The trouble is, of course, that there are not many standard 6.0L Powerstroke engines around anymore, which is perhaps the most eloquent proof that bulletproofing them worked really well.