When a customer asks you, which is better- synthetic or mineral engine oil, do you have a ready answer, or do you merely repeat much of the misinformation and sales talk that is so prevalent on the internet? Many of us could be forgiven for prevaricating on the issue, since many of the claimed advantages of synthetic engine oil cannot be quantified in meaningful ways due to differences in the type/brand of synthetic oil in question, different driving styles, varying operating conditions, and even the type of vehicle and its prescribed oil change interval.

However, and for the moment leaving aside all the imponderable questions, as experienced technicians we should be aware, and take notice of the multitude of independent and objective studies that show that synthetic engine oil has several major, and quantifiable advantages over even the most advanced mineral engine oils. This article will explore some of the advantages of synthetic engine oil, these being improved lubricity, increased resistance to oxidation, and increased stability in terms of viscosity, staring with this question-

One of the most persistent misconceptions about synthetic oil among professional technicians and the public alike is that synthetic oil is somehow not a petroleum-based product. While this is not true, it is so only up to a point, which we will get to later.

When oil is said to be synthetic, it is synthetic only in the sense that it was not produced by distilling crude oil, but instead, through a process in which various hydrocarbon-rich gases like carbon dioxide, methane (and others, depending on the desired characteristics of the oil), are condensed into a liquid. However, the resulting base oil is largely similar to base oil that was refined from crude oil in the sense that by itself, it cannot provide sufficient lubrication in any engine.

Thus, the synthesised base oil is improved by the same additives in the form of friction modifiers, anti-foaming agents, and detergents that are used to augment the lubricating properties of mineral oil. It should be noted though that as with mineral oil, many additives are solids that need to be dissolved in “carrier oil”, with the result that up to about 20% of any given volume of synthetic oil is taken up by substances that are not oil. In fact, even in so-called “premium” synthetic oil, the carrier oil is often nothing but a light grade of mineral oil, which brings us to the fact that-

As stated elsewhere, it is not true to say that synthetic engine oil is not petroleum-based, but there are exceptions to this rule. In some cases, some oils marketed as “synthetic”, or even as “100% synthetic”, are highly engineered mineral oils that were distilled from crude mineral oil.

There are several reasons for this; foremost among them being that no regulating body anywhere in the world has developed specifications and standards that clearly define what synthetic oil is, or should be, and this is true of synthetic/mineral oil blends as well. As matters stand now, no regulations exist that specify the volume of mineral oil relative the synthetic that must be present in a container for that blend to qualify as blended oil.

In fact, the API (American Petroleum Institute) which is the regulating body with the widest reach and most influence in the world, has deleted all references to “synthetic oil” from its data sheets and information pages that collectively, makes up the J300 Standard. In essence, the J300 standard is maintained by the SAE (Society of Automotive Engineers), and its purpose is to regulate the viscometric characteristics of both mineral and synthetic mono-, and multigrade motor oils.

A secondary reason is that technology has improved to the point where mineral oil can now be subjected to chemical engineering process that yield mineral oil that compares favourably with purely synthetic oils in all important aspects, and in some cases, even outperforms some synthetic oils.

As a practical matter though, several recent court judgments in both the USA and Europe have stated that because of the enhanced properties of some chemically engineered mineral oils, these oils are virtually indistinguishable from purely synthetic oils, and that therefore, these oils can be legally marketed as “synthetic oil”, even though these oils are distilled from crude mineral oil.

While all of the above is very interesting and illuminating, its only purpose is to clear up some misconceptions about synthetic oil. The fact remains that purely synthetic oils from reputable manufacturers have a few distinct advantages over mineral oil in general, which brings us to-

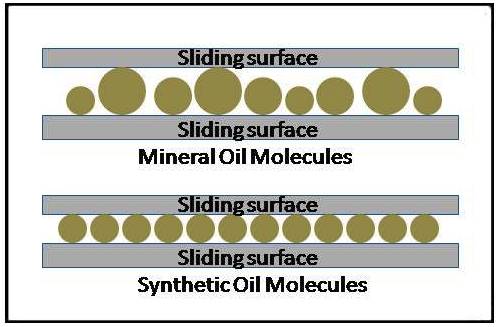

The diagram above illustrates the fundamental difference between mineral and synthetic oils. In this diagram, the brown balls represent oil molecules, while the sliding surfaces can be any two metal surfaces that need to be kept apart by a film of lubricating oil to prevent direct contact.

As can be seen in the bottom representation, the oil molecules are all the same size, and they are evenly spaced. This is a direct result of the manufacturing process, since the individual gasses that were condensed all consist of molecules that are identical in their structure. Moreover, during the condensation process, the individual gas molecules combine with other gas molecules in predictable ways, which means that the resulting oil molecules are also the same size.

Since the oil molecules are the same size, the friction load is shared equally between all the oil molecules, thus reducing the amount of energy required to move sliding surfaces relative to each other, which means that less fuel is required to do the same amount of work. As a practical matter, this allows engine designers to design engines with closer engineering tolerances, which in turn, improves oil control on cylinder walls, thus reducing emissions.

In contrast, as can be seen in the top representation, mineral oil molecules vary greatly in size, which means that they are not evenly spaced, and can therefore not share the friction load equally. While modern chemical engineering processes have been reducing the size differences in mineral oil molecules in recent years, the fact is that differences in the chemical composition of different types of crude oil makes it impossible to produce mineral-based engine oil in which the molecules are perfectly uniform.

What this means in practice, is that only some mineral oil molecules contribute to the formation and maintenance of oil films between sliding surfaces, with the rest simply slipping through the gaps, so to speak.

However, there is more to engine lubrication than the sizes of individual oil molecules. One such factor is the fact that since imperfections in sliding surfaces are purposely designed to hold minute quantities of oil, which is particularly important on cylinder walls, these imperfections will hold more oil if the molecules were all of the same size.

Another factor is the fact that base oil, regardless of whether it is synthesised from gas or distilled from crude oil, provides almost no lubrication by itself, which is why all lubricating oils contain additives like friction modifiers and viscosity improvers, among others. Thus, it can be argued that the primary purpose of the base oil is to keep the additives in suspension, and to transport the additives around the engine as the oil circulates.

In practice though, all reputable oil manufactures use additive packages that are largely proprietary. However, despite specific differences in relative concentrations of additives in proprietary additive packages, the volumes of different additives reputable oil manufacturers add are calculated to ensure not only that all the additives are compatible with each other, but that the total volume of additives mix uniformly throughout the total volume of oil in the engine, and it is here where synthetic oils really shine. Here is-

As we know, “viscosity” is defined as a liquid’s resistance to both flow and shear forces under the force of gravity, and for our purposes, this value is commonly expressed as “cST”, with “cST” standing for centi-Stoke; one centi-Stoke being equal to 1 mm2/sec, according to ASTM and ISO standards D445 and 3105, respectively.

Oil data/spec sheets usually list two cST values; one at 400C, and another at 1000C. During the testing or certification process of oil formulations, the oil (at a temperature of 400C) must flow through a standardised orifice at a minimum rate, with the flow rate being a function of the oil’s formulation. This rate is converted to a cST value, which is an indication of how easy or difficult it would be for that oil to flow through an engine at very low ambient temperatures.

The test is repeated with the oil heated to 1000C, but in this case, the derived cST value is an indication of how much the oil will “thin out” at high ambient temperatures. In practice, the smaller the difference is between the two cST values, the more stable an oil formulation is in terms of its viscosity. Put in another way, it means that the oil will have much the same “thickness”, or resistance to flow over a wider range of engine temperatures than a mineral oil formulation with a large difference in its low and high temperature cST values.

While in the Australian context this may not feature strongly in terms of low ambient temperatures, it does have a direct bearing on how well a synthetic oil formulation performs in high ambient temperatures, where engine lubrication depends on the oil being thermally stable.

However, viscosity is only one factor of the complex problem of providing proper engine lubrication; there are other equally important factors, with the principal ones being-

Viscosity as a function of formulation

Synthetic oils intended for use in automotive applications are not created equal, and as with all other consumer products, there are always levels of quality that may differ dramatically between brands and manufacturers.

That being said though, reputable oil manufacturers design base oils to have very specific characteristics, and especially in terms of viscosity by means of varying the relative concentrations of the gasses used to “brew” the base oil. However, a common misconception about synthetic oil is that it is too “thin” to provide proper lubrication- with the corollary being that the “thicker” an oil formulation is, the better it lubricates.

Nothing could be further from the truth; the fact is that the “thickness” or “thinness” of any given oil formulation has very little, if anything to do with how well oil performs under any given set of operating conditions. What is vastly more important is how well any given engine oil formulation is able to transport critically important additives around the engine throughout the temperature range that oil was designed to be used in, since it is the additives that provide the actual lubrication, and not the base oil.

As a practical matter though, one of the reasons why synthetic oil provides superior lubricity is the fact that its molecules are all the same size. Since there are no perfect oil circulation systems, the equally sized molecules of synthetic oil flow around the engine easier over a wide range of engine and ambient temperatures. In contrast, the unevenly sized molecules of poorly formulated mineral oil sometimes tend to separate out according to size and mass under temperature extremes at some spots in most oil circulation systems.

Thus, the combined effect of being thermally stable and having equally sized molecules translates into the fact that the dispersion of additives is (almost) uniform, which in turn, means improved lubrication as compared to mineral oil in which the dispersion of additives is not always uniform.

High resistance to oxidation

The single biggest factor that degrades engine oil is not so much the heat of normal engine operation, but rather contact with oxygen, which in combination with heat, acts as a catalyst in many of the chemical actions/reactions that occur in engine oil.

For instance, mineral oil that is distilled from crude oil contains multiple carbon-carbon bonds, which are expressed as “–C=C–“ bonds. At high temperatures, these double carbon bonds are broken up into shorter molecular chains by oxygen molecules to form acids known as carboxylic acids. This reaction has two effects; first, the oil “thins out” as a result of the shorter molecular chains being formed, and secondly, the newly-formed acid attacks exposed metal surfaces to form salts (which liberates explosive hydrogen gas) when the carboxylic acids combine with waste products from corroded metal surfaces.

While synthetic oil is not altogether immune to these processes, the molecular chains that make up synthesised base oil are highly resistant to the effect of oxygen molecules on them, which means that in practice, the degradation process of synthetic oil is greatly retarded.

Lack of impurities in synthetic oil

Since synthetic oil is synthesised from gasses that are essentially pure, the resulting base oil does not contain any of the paraffinic waxes, gums, and varnishes that are present in all mineral oil formulations, although trace amounts of sulphur may be present in most synthetic formulations.

In practice, when the volatile substances in mineral oil evaporate beyond a critical point the waxes in the oil start to form crystals, some of which may be trapped in the oil filter, which obviously reduces the filter’s efficiency. In extreme cases, the formation of wax crystals can decrease the viscosity of the oil to the point where the oil transforms into an almost jelly-like substance that is impossible to pump around the engine.

Moreover, the combination of the presence of wax crystals and depleted additives can reduce even the best mineral oil’s lubricity to the point where direct metal-to-metal contact occurs between sliding surfaces, with catastrophic engine failure following soon after.

Bear in mind though that synthetic oil is NOT some magic formula that never needs replacing. The additives in synthetic oil also become depleted over time, but because synthetic oil is vastly more resistant to oxidation than any mineral oil due to the nature of its molecular structure, the process of degradation or depletion of additives is greatly retarded, which is the primary factor that makes synthetic oil last longer than mineral oil.

Although limited space precludes an in-depth treatment of the synthetic-mineral oil debate, the above should be sufficient to enable any technician to say to his customer that yes, synthetic oil is better than mineral oil.

However, it is imperative that only products of the correct grade/formulation from reputable manufacturers such as Penrite Oil be used or recommended, since these products are certified by the API (American Petroleum Institute) to comply the relevant standards and specifications for that product. Also, note that since even API-certified synthetic oils have finite service lives, it is important that oil changes be performed strictly in accordance with the vehicle manufacturer’s recommended oil change intervals to avoid negating all the demonstrable benefits that come with synthetic engine oil.