How often does it happen to you that you are absolutely sure about your diagnostic conclusions only to discover that you are not only wrong but that you have been looking for the problem in the wrong place?

If the truth were told, we have all fallen down diagnostic rabbit holes, especially when we were not involved with the original problem and its associated repair attempts. In an ideal world, none of us would accept jobs that involve repairing other people’s repairs, but when business is slow, we must do what we can to survive. Thus, in this article, we recount the tale of how we resolved a poor performance issue on a Nissan Navara that was caused by both worn timing chains and a mis-indexed flywheel. Before we get to specifics, though, let us state-

We knew the customer who presented us with his 2009 Navara as a tyre-kicker, who had no compunction about letting us spend hours working out quotes and estimates and then taking the job elsewhere.

In the long time that we knew him, he never used our services, so when he arrived at our door late one afternoon, along with his 2009 VQ40DE-engined Nissan Navara on the back of a recovery truck, we were not particularly glad to see him. However, this time, he apologised for the many times he took our quotes and estimates to our competitors and asked if we could help him with his truck that had stalled on him while he was driving home.

Our first inclination was to refer him to a competitor, but since we were going through a quiet time, we decided to hear him out. This is what he told us-

According to the (potential) customer, he had been having issues with the truck’s poor performance and high fuel consumption ever since he had replaced the clutch on the truck about 18 months before. While he could deal with the loss of power, the “weird” noise from the engine that varied with the engine speed had been getting steadily worse of late, until earlier in the day, when the engine suddenly died. He also stated that there were no illuminated warning lights on the dashboard immediately before the engine died, or in the previous several weeks.

Since we have never worked on this vehicle before, we knew nothing of its history. Therefore, we asked all the right questions, including-

Here is what he replied-

We had serious reservations about accepting this job, but since a) the Navara seemed to be in an excellent condition, b) the customer seemed to give honest responses to our questions, and c), we did not have much work just then we accepted the job. It was past closing time by then so we did the required paperwork, offloaded the vehicle, pushed it into an empty bay, and closed up for the night. The customer left with the recovery truck, but promised to be back the next afternoon to see-

The next day, we verified the battery’s state of charge, and since it was fully charged, our inspection started with a comprehensive diagnostic scan. Somewhat to our surprise, though, there were no fault codes stored in any control modules.

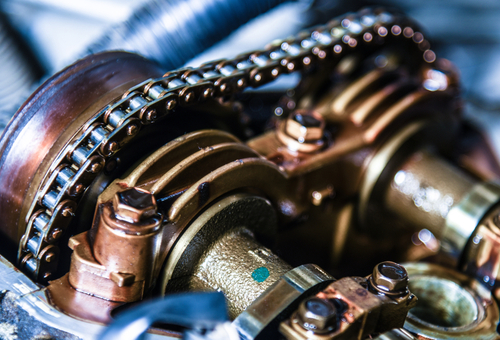

Next, we cranked the engine, which revealed the problem. There was clearly no cylinder compression because the engine spun freely. We all knew that VQ40DE engines had problematic timing chains, so this could mean only one thing. One or more timing chains had jumped teeth, or worse, snapped, and since VQ40DE engines are interference engines, it was almost certain that the pistons had likely destroyed all or most of the valves.

We did not know at what speed the engine was running when it died, so there was a possibility that the pistons had escaped serious damage, but we would only know that for sure once we had removed the cylinder heads. Thus, we called up the customer with this bad news, and to our surprise, he permitted us to remove the cylinder heads without first insisting on a binding quote.

We do not need to delve into the finer details of what followed next, beyond saying-

Thus, long story short; we fitted the new cylinder heads, along with the upgraded timing kit that was developed to resolve the timing chain issues all VQ40DE engines suffered from up to about the middle of 2009. Our chief mechanic supervised the installation of the timing chains, guides, and tensioners, and took it upon himself to set the valve clearances to their recommended values, which brings us to-

After four days, which include waiting time for parts and double-checking all wiring, fuel, ignition, cooling system, and engine vacuum connections we were ready to start the engine, which, it did, but only after some extended cranking.

However, the CHECK ENGINE light lit up almost immediately, but despite our best efforts, we could not get the engine to run at speeds below about 2000 RPM. On the bright side though, it did settle into a very rough idle after it had warmed up a bit. Nonetheless, we could not raise the engine speed without the engine stalling immediately.

To say that we did not expect this turn of events would be an understatement. The observed symptoms appeared to indicate a serious valve timing issue, and while we all tend to doubt the abilities of others (and ourselves) at times like this, it was at the same time almost inconceivable that the chief mechanic could have gotten the engine timing wrong.

In fact, during the more than fifteen years the chief mechanic had been in this writers’ service, he had never made a serious mistake, let alone getting the valve timing wrong on a simple Nissan V6 engine- on any engine, for that matter. Still, the evidence pointed to a valve timing issue, but just then, the resident diagnostician arrived with his Nissan-specific scan tool, which he proceeded to plug into the DLC.

The scan took only about two minutes to produce a result. This result was the presence of two fault codes, these codes being- P0011 – “INT/V TIM CONT-B1", and P0021 – “INT/V TIM CONT-B2". In translation, these codes mean that the intake camshafts on both banks are over-advanced.

At this point, we all took several steps back to consider the possibilities. One such possibility was that the chief mechanic had indeed gotten the valve timing wrong, which raised the further possibility that one, or several, or all the valves had suffered damage- again.

Another possibility was that we might have some kind of camshaft position sensor issue, which the diagnostician doubted because he checked for sensor codes, and there were none.

The last possibility was that the valve timing was indeed off, but checking that meant dismantling much of the engine again, but one way to check that would be to do a relative compression test with an oscilloscope. However, the test showed that all cylinder compression values were equal and stable at just less than 13.0 kg/cm2 at a cranking speed of 300 RPM.

Therefore, the valve timing was unlikely to be a factor in this problem, especially since another test to check the intake/exhaust camshaft correlation on both banks showed no issues.

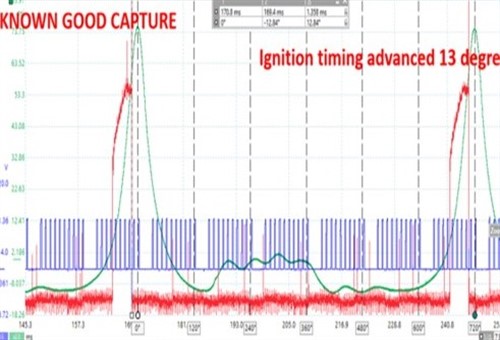

Unfortunately, though, we did not add an ignition trace to the compression test, so the diagnostician ran another test that compared peak compression pressures with ignition events. This is what we saw-

As shown by the circles, the ignition was advanced by a whopping 39 degrees, which was hugely surprising, to say the least. We knew that at cranking speed, the ignition timing should be at about 13 degrees BTDC, but we were not exactly sure. Therefore, we looked for and found a known-good ignition/compression comparison waveform online, and this is what it showed-

This waveform clearly shows an appropriate ignition timing setting, and even though none of us had ever seen this particular ignition timing problem on a VQ40DE engine, we agreed that we were dealing with an ignition trigger input signal issue.

We also agreed that the crankshaft position sensor, which supplies the input signal via a reluctor ring on the flywheel, was unlikely to be defective since the ignition timing was consistently advanced by 39 degrees. There were no fluctuations in the trace we took, which showed that the sensor was working properly.

As a practical matter, that left us with two possibilities. The first was the possibility that the mobile mechanic who replaced the clutch fitted a flywheel intended for use on a different version of the VQ40DE engine, of which there were several. The other possibility was that the mobile mechanic had used the correct flywheel, but he had gotten the flywheels’ indexing wrong. Both possibilities would explain the engine’s poor performance and high fuel consumption that started immediately after the clutch replacement, but that knowledge did not help us in the least. In this instance, we needed to know the exact cause of the problem, which brings us to-

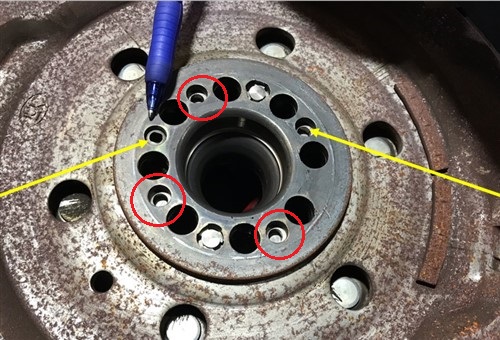

If you are new to Nissan’s VQ40DE engine, you may or may not know that the flywheels on all the versions of this engine can fit in any of five different indexing positions. Thus, unless you clearly mark the flywheels’ position relative to the crankshaft when you remove it for any reason, you only have a one-in-five chance of reinstalling it correctly. Consider the image below-

In this example of a VQ40DE flywheel, the two yellow arrows and three red circles indicate the five possible mounting positions, which as you will notice, are not spaced equally. Note also the eight boltholes that are spaced equally around their common PCD.

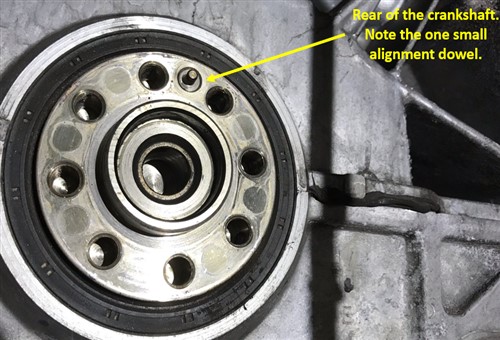

Each of the possible locating holes accepts a small locating pin in the crankshaft, as shown below-

In addition, the ECU uses three gaps (that are spaced 20 degrees apart) between the teeth on the reluctor ring to calculate the position of piston number 1 to calculate the injection timing on cylinder number one during engine starting.

Therefore, in practice, while the three gaps in the reluctor rings on all VQ40DE flywheels are spaced 120 degrees apart, the three gaps on any VQ40DE flywheel must be indexed to a particular mounting position to establish a valid ignition timing strategy on cylinder number one. However, the problem with this arrangement is that replacement flywheels do not carry any kind of mark or indication to show which mounting position one must use on which version of the engine.

In this case, though, the only thing we could do was to remove the transmission so we could correct the flywheel’s indexing. We were not exactly sure how to do that yet, but looking for information about this issue revealed the fact that when the variable valve timing is at zero degrees, i.e., the camshafts are in their base positions, this engine will only set valve timing codes if the deviation from set values exceeds 10 degrees.

NOTE: For example, if the intake valve timing is off by more than 10 degrees to either side of 240 degrees (with no valve timing adjustment via the VVT system), the ECU will set a valve timing code. Similarly, the ECU will only set valve timing codes if the exhaust valve timing deviates by more than 10 degrees from 244 degrees.

By this time, we had the flywheel exposed, so now we had to figure out how to correct the flywheel’s indexing. Here is the short version of our process-

We were working blind, without any sort of technical information, but we assumed that the variation brought about by the worn timing chain tensioners had somehow partly compensated for the flywheel's incorrect indexing-at least until the chains broke. If the deviation had not compensated for the incorrect indexing, the engine would not have run at all. We used the fact that the valve timing was now demonstrably correct to substantiate this theory.

However, since the flywheel had eight boltholes, moving it one hole would change its position by 45 degrees. i.e., 360 divided by 8 = 45. Moving it by two holes would change its position by 90 degrees, but if we moved it by three holes, its position would change by 135 degrees.

In practice, this placed one of the gaps in the reluctor ring only 15 degrees (135 degrees minus 120 degrees) from the position of the crankshaft angle sensor. None of us thought that a difference of 2 degrees between our indexing and the ignition timing setting we saw on our known-good trace would make any meaningful difference so we moved the flywheel by three boltholes, and reassemble the vehicle, which brings us to

Nothing bad happened. We cranked the engine; it fired up immediately and ran at a smooth idle. Just to be sure, we switched it off and restarted it multiple times. It ran smoothly every time, and it must be said, without “weird” mechanical noises coming from the engine.

Next, the diagnostician and the chief mechanic connected a scan tool to the DLC and went on an extended test drive. Again, nothing bad happened. No new fault codes appeared, and the live data they collected on (particularly) the fuel trims and operation of the variable valve timing system revealed no issues- active or pending, which leaves us with this-

In an ideal world, we would always have all the service information and diagnostic clues we need ready at hand to solve tricky diagnostic issues. Sadly, we do not, but we have the two next best things: we have our problem-solving skills and our ability to reduce complex problems to their simplest form. And, of course, we have oscilloscopes to create visual representations of what is happening inside an engine.

In this particular case, though, we did not have enough information to define the problem. We did not know by how much the worn timing chains/tensioners had retarded the valve timing, and we did not know that the indexing of the flywheel was off. Nonetheless, the valve timing retardation was probably high enough to offset the flywheels' wrong indexing at least partially, so somewhat counter-intuitively, two defects had combined to keep the engine running, albeit poorly. Then again, stranger things have happened, and they will almost certainly happen again.