What do you do when you do an inspection on a vehicle with an automatic transmission, and you discover that the transmission has a "lifetime" fill, as many, if not most automatic transmissions now have? Do you merely tick the appropriate box on your checklist, and let your customer believe that the fluid level in his transmission is OK? Do you tell your customer that the transmission fluid level is best checked by a dealership because you do not have access to the required equipment or technical/service information, or do you attempt to check the fluid level yourself by unscrewing a drain or filler plug?

These are sometimes difficult choices to make, and especially so if you are not an expert on automatic transmissions, since each possible choice has potentially expensive consequences for you, your employer, and your customer. Thus, in this article, we will discuss some of the pitfalls of lifetime transmission fills from our perspective as technicians, and provide some tips on how to check fluid levels on at least some transmissions with lifetime fills. Let us start by stating -

Even those among us who are not expert automatic transmission techs have heard stories of transmissions with lifetime fills seizing up, blowing up, disintegrating, or otherwise breaking down, and in many of these cases, the principal cause of the failure is directly attributable to dirty or degraded fluid. This is especially true of vehicles that are used for towing but are not fitted with OEM towing packages that feature a greater capacity to manage the transmission fluid’s temperature to prevent the premature and excessive degradation of the fluid.

You may or may not know that like engine oil, transmission fluids consist of base oils that are augmented by various additives like friction modifiers, viscosity improvers/stabilisers, corrosion inhibitors, detergents, and others that include various kinds of anti-foaming agents and flocculants that keep contaminants in suspension in the fluid. However, while transmission fluids are not subjected to degradation through contact with oxygen to the same degree as engine oil, and therefore do not suffer from sludge formation at the same rates as engine oils, transmission fluids are not filtered as effectively as engine oil.

Moreover, while the additives in transmission fluids do not degrade as quickly as the additives in engine oils do, due to lower operating temperatures and reduced oxidation rates, the rate of mechanical wear in automatic transmissions is several orders of magnitude higher than the wear rates in engines.

Very high wear rates produce higher metal particle loads, and while a large percentage of wear particles is ferrous, and can therefore be captured by strategically placed magnets, a significant percentage of wear particles is non-ferrous, and can therefore not be removed from the fluid by magnets. The only place for non-ferrous particles to go is into the transmission’s filter, which as we know, has a finite service life.

If you have not had much exposure to automatic transmission servicing and repair, you may not know that the single biggest cause of transmission failures and malfunctions is the combination of degraded fluid and high wear particle loads. Degraded fluid with “worn out” friction modifiers has a reduced capacity to lubricate moving parts, and if you add high numbers of wear particles that pass through, or by-pass an internal filter, you begin to see-

In practice, the above issues typically cause symptoms that include but are not limited to-

So what does any of the above have to do with lifetime transmission fills? Simply this; on "normal", serviceable transmissions, it was often possible to resolve some, or (sometimes) even all of the above symptoms before they could turn into major issues by performing a simple transmission fluid and filter replacement.

Of course, simple fluid and filter replacements could not always save an automatic transmission, but the point is that on a transmission with a lifetime fill, one cannot even take a sample of the fluid to check its condition without running the risk of reducing the fluid level to below a point where damage to the transmission might occur, so-

Even those among us who are not expert automatic transmission techs have heard stories of transmissions with lifetime fills seizing up, blowing up, disintegrating, or otherwise breaking down, and in many of these cases, the principal cause of the failure is directly attributable to dirty or degraded fluid. This is especially true of vehicles that are used for towing but are not fitted with OEM towing packages that feature a greater capacity to manage the transmission fluid’s temperature to prevent the premature and excessive degradation of the fluid.

You may or may not know that like engine oil, transmission fluids consist of base oils that are augmented by various additives like friction modifiers, viscosity improvers/stabilisers, corrosion inhibitors, detergents, and others that include various kinds of anti-foaming agents and flocculants that keep contaminants in suspension in the fluid. However, while transmission fluids are not subjected to degradation through contact with oxygen to the same degree as engine oil, and therefore do not suffer from sludge formation at the same rates as engine oils, transmission fluids are not filtered as effectively as engine oil.

Moreover, while the additives in transmission fluids do not degrade as quickly as the additives in engine oils do, due to lower operating temperatures and reduced oxidation rates, the rate of mechanical wear in automatic transmissions is several orders of magnitude higher than the wear rates in engines.

Very high wear rates produce higher metal particle loads, and while a large percentage of wear particles is ferrous, and can therefore be captured by strategically placed magnets, a significant percentage of wear particles is non-ferrous, and can therefore not be removed from the fluid by magnets. The only place for non-ferrous particles to go is into the transmission’s filter, which as we know, has a finite service life.

If you have not had much exposure to automatic transmission servicing and repair, you may not know that the single biggest cause of transmission failures and malfunctions is the combination of degraded fluid and high wear particle loads. Degraded fluid with “worn out” friction modifiers has a reduced capacity to lubricate moving parts, and if you add high numbers of wear particles that pass through, or by-pass an internal filter, you begin to see-

In practice, the above issues typically cause symptoms that include but are not limited to-

So what does any of the above have to do with lifetime transmission fills? Simply this; on "normal", serviceable transmissions, it was often possible to resolve some, or (sometimes) even all of the above symptoms before they could turn into major issues by performing a simple transmission fluid and filter replacement.

Of course, simple fluid and filter replacements could not always save an automatic transmission, but the point is that on a transmission with a lifetime fill, one cannot even take a sample of the fluid to check its condition without running the risk of reducing the fluid level to below a point where damage to the transmission might occur, so-

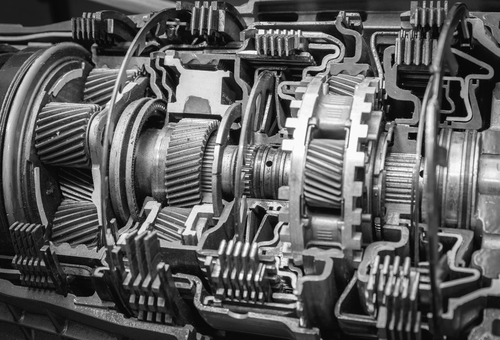

Put simply, lifetime transmission fills leave us up the proverbial creek without paddles, given the fact that we cannot even check fluid levels or the condition of the fluid without running the risk of causing damage to the transmission. There are no clear answers to the question of why car manufacturers make it impossible for us to do these things, but one theory has it that modern automatic transmissions and their control systems have become so complicated that car manufacturers do not trust anybody except their own trained technicians do anything on their transmissions. Given the internals of the automatic transmission shown above, there might well be something to this theory.

Nonetheless, whatever it is that made carmakers think that transmission fluid will not degrade over time is less important than the facts a) that almost all modern automatic transmissions are far more sensitive to fluid levels than ever before, and b), that there is a closer relationship between the level and temperature of transmission fluid than ever before. In fact, some transmission designs depend on the expansion rate of transmission fluid as a means to ensure that everything in the transmission is properly lubricated.

Therefore, overfilling a modern transmission with a lifetime fill means that the fluid can expand to the point where the transmission is too full, which causes not only overheating of the transmission, but also an excessive pressure can, and does push input and output shaft oil seals out of their housings. As might be expected, pushed out seals will result in a complete loss of all the transmission fluid in a matter of seconds.

Thus, against the above background, we return to the question of what to do when a customer asks you to perform a check or inspection that includes-

At this point, you have two choices. The first is that you can explain all of the above to the customer and decline to check the fluid because you neither have the tools, nor access to the required service information. It has been this writer’s experience that some customers accept this explanation, but others do not and insist that since you are the expert, you must be able to do something as simple as check the fluid in his sealed transmission.

The second option might allow you to check the fluid level on some transmissions, but until the Mandatory Data Sharing Law becomes operative, doing this requires you to purchase both an expensive subscription to a third-party resource to obtain the relevant service information and a specialized dipstick for the vehicle. Note though that this option only applies to vehicles that have a dipstick tube on the transmission.

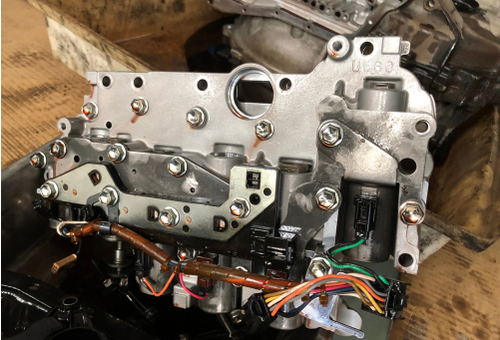

The image above shows a specialised dipstick* that works on a variety of GM transmissions, but note the graduations on this version. In this case, the dipstick is inserted into the dipstick tube until it hits the bottom of the sump. The fluid level is then read off the graduated scale, and compared to a temperature chart, with the relationship between the fluid temperature and the indicated fluid level being the principal factor that determines whether (or not) the fluid level is correct.

*Many aftermarket tool suppliers supply OEM-equivalent dipsticks for almost all vehicle makes and models in the local market that have dipstick tubes. Note though that in all cases, the reading on the dipstick has to be compared to the relevant temperature chart for a specific application to obtain reliable results.

Therefore, provided you have access to the relevant service information, checking lifetime fill levels on vehicles with dipstick tubes is relatively easy. However, obtaining an actual transmission fluid temperature with a scan tool is critically important because in some cases, determining the fluid level accurately requires that you take several readings at different (fluid) temperatures with different gears selected, or at different engine speeds.

So, unless the vehicle you are inspecting has a transmission leak, are you prepared to go to the trouble and expense involved with checking the fluid level? After all, if the fluid is not leaking out, it can't go anywhere, right? More to the point though, are you prepared to spend a minimum of one hour checking a transmission fluid level when you have a backlog of work requiring your undivided attention?

These are not easy questions to answer, especially if you are not your own boss- and far be it from this writer to tell anybody how to act in this kind of situation. However, when this writer discussed this issue with both dealership technicians and workshop supervisors for several vehicle brands, it was illuminating to learn that some dealerships typically only check fluid levels on sealed transmissions when there are fluid leaks present.

If no leaks are present, the operation of the transmission is satisfactory, there are no mechanical sounds present, and scans turn up no fault codes, some of the dealers this writer spoke to said that they inform the customer that they can’t guarantee that the transmission fluid is up to the required mark. Additionally, they also inform their customers that they can’t determine the quality or condition of the fluid because they can’t extract a sample of fluid from the sealed transmission.

It is not for this writer to express an opinion on the ethics or wisdom of the decisions some dealerships make. However, for what it’s worth, this writer leans towards the argument that if it is possible to check the fluid on some sealed transmissions, the levels on these transmissions should be checked, subject to the customer knowing and understanding that doing this will add at least one additional hour of labour to the final bill.

If, however, you are working for a boss (other than yourself) you may not have a choice in the matter, and you may have to check fluid levels in-

Contrary to popular belief, it is possible to check fluid levels on some sealed transmissions that do not have dipstick tubes, but doing so involves following procedures that range from two pages long to veritable volumes of instructions than can be ten (and more) pages long*. Worse, though, in some cases, you can only do this with OEM tools, and it can take as long as four to five hours.

* TSB L-SB-0011-13 dated February 26, 2013, is a good case in point. This tome stretches over eleven pages and it describes the process of checking and adjusting the transmission fluid level on some Lexus models. This process is far too long and complicated to reproduce here even in abbreviated form, but it should nevertheless be seen as required reading if you ever become tempted to check transmission fluid levels on Lexus vehicles.

Nonetheless, the fluid levels of some transmissions without dipstick tubes can be checked, but the first thing you should be aware of is that in all cases, the fluid level can only be determined accurately if the fluid is at a specific temperature, which is usually in the 200C to 550C range. Therefore, in some cases, you may have to warm the fluid by driving the vehicle, while in other cases you may have to keep the vehicle overnight to ensure the fluid is at the specified temperature before you begin the process.

To illustrate how complex this process can be, we will use two examples of transmissions that are in common use. It is perhaps worth noting that the OEM service information for the procedure is only a few pages long for both examples, so let us look at some of the things you need to do check the fluid levels on some GM and Toyota transmissions. Let us start with the-

General Motors 4T40-E & 4T45-E transmissions

These transmissions are used on many small and compact FWD GM vehicles made from 1995. The prescribed procedure stretches across two pages, but here is an abbreviated version-

1) Place the vehicle on a level hoist, and use a high-end scan tool to take the fluid's temperature. If the reading is too high or too low, either drive the vehicle to heat the fluid or wait until the fluid cools down to the correct temperature.

2) With the vehicle back on the hoist and the fluid at the correct temperature (refer to the service information for this), locate the fluid-level inspection plug on the transmission. Refer to the service information to identify the correct plug, because an identical plug is located close by, but this plug is used to check line pressure. Unscrewing the wrong plug can cause a serious loss of fluid. Place a suitable drainage container under the correct plug to catch the fluid that might escape when you remove the inspection plug but do not remove the plug at this point.

3) Locate and remove the (plastic) filler plug on top of the transmission casing, and insert a clean funnel into the hole.

4) Start the engine, and move the gear selector through all possible positions, pausing or at least three seconds before moving the selector to the next position. Note that this procedure must occur with the engine running at idling speed.

5) Place the gear selector in the “PARK” position, and remove the inspection plug carefully while the engine is idling. The fluid may be hot and some of it might rush out, so take care not to have it splash onto your hands and face.

6) If fluid flows from the inspection hole, allow it to continue flowing until it slows to a slow drip. At this point, the fluid is at the correct level, and you can replace the plug. Be sure to tighten it properly.

7) If, however, no fluid flows from the inspection hole with the engine idling and the gear selector in “PARK”, slowly add some fluid of the recommended grade and formulation through the funnel in the filler plug until it flows from the inspection hole. Allow the flow to slow to a slow drip before replacing the inspection plug. Be sure to tighten the plug properly.

NOTE: The series of actions described above is a grossly abbreviated/simplified version of the OEM service information, and it should therefore not be used as your only source of information when you check fluid levels on these GM transmissions.

Toyota AB60E & AB60F transmissions

These six-speed transmissions are in use mainly in 2007 (and onwards) Tundra trucks and Sequoia SUVs. Unlike the GM transmissions discussed above, though, the OEM service information that describes checking the transmission fluid level stretches across fourteen pages, two of which describe the nature and use of a special tool, without which it is impossible to add fluid to the transmission.

For the most part, the process of checking the fluid level in these Toyota transmissions is largely similar to that of the two GM transmissions mentioned above, but there are some notable exceptions to this on some Toyota vehicles that include the following models-

The above vehicles have specific precautions and procedures that are best obtained from current service information, but some requirements that apply to all Toyota AB60E & AB60F transmissions include the following-

1) Fluid levels can only be determined accurately if the fluid temperature is between 460C and 560C.

2) Vehicles that are factory-fitted with towing packages have a thermostat in the fluid cooling system to regulate the fluid's temperature in much the same way that a conventional engine cooling system is regulated by a thermostat. This thermostat must be pinned open during the fluid level checking process to ensure that all fluid lines and the fluid cooler are full of fluid during the process.

3) While a clean, uncontaminated suction gun can be used to add transmission fluid, this is difficult, cumbersome, and likely to spill more fluid than is pumped into the transmission. In practice, using the prescribed Toyota-approved equipment can save you at least an hour of labour.

4) AB60E & AB60F transmissions require the use of Toyota’s proprietary transmission fluid formulation known as “WS” or Toyota World Standard Fluid, which is only available through dealerships, which leaves us with this-

The limited information provided here is solely intended to illustrate the potential difficulties and dangers involved in checking fluid levels on sealed transmissions. Therefore, it should be noted that under no circumstances should anyone attempt to check the fluid level on any sealed transmission unless they have access to current and updated service information on the one hand, and they have a thorough understanding of the entire process, on the other.

Of course, this is not the same as saying that nobody should ever attempt to learn how to check fluid levels on sealed transmissions. When the Mandatory Data Sharing Law becomes operative, many customers will likely expect us to do this, but until then, we recommend that you weigh your options very carefully, because there is an almost unlimited potential to make mistakes that could ruin some extremely expensive transmissions in very short order.

Put in another way, we recommend that you choose between doing these inspections properly and according to prescribed service procedures or not doing them at all- provided of course, that you inform the customer why you chose not to check his transmission fluid. Any other choice is an exceedingly bad idea, so be sure to cover both yourself and your employer against liability by choosing to do the right thing when you deal with sealed automatic transmissions.