We have all experienced that sinking feeling when a customer presents a vehicle with what appears to be a parasitic battery drain, because as we know, this type of problem can take many hours, and in some cases, days to resolve. In recent years though, several manufacturers have developed thermal imaging systems that use infrared radiation in the range of frequencies that occur most commonly on motor vehicles to create visual representations of the heat signatures of vehicle parts and components, including wiring. In practice, a visible picture of the heat sources in a vehicle is an almost foolproof diagnostic aid and in this article, we will take a closer look at what thermal imaging is and how it can help you find and resolve issues that may not be detectable in any other way, starting with this question-

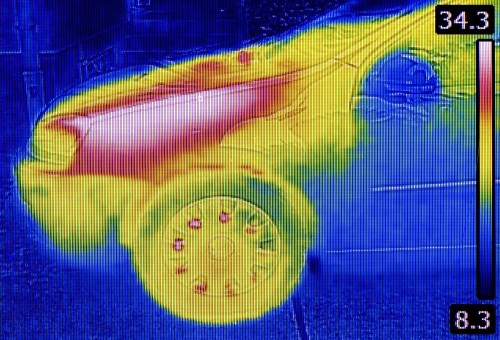

While infrared light frequencies have been used to image objects in the scientific arena for a long time, it only became available as a viable and cost effective diagnostic aid in the car repair industry in the comparatively recent past. Consider the image at the top of this article; this image was taken with a professional-grade thermal imager that was developed specifically for the automotive repair industry, and it shows the heat signature of a vehicle engine soon after the engine was switched off.

In this image, the hottest part of the engine is shown in white, while the red represents the overall temperature of the engine compartment. Note that the red spots in the front wheel represent the parts, and the temperature of those parts of the brake rotor that can be seen through the spokes of the rim, which brings us to-

All objects that we can see radiate energy in the form of electromagnetic radiation with frequencies that range from about 400 to about 700 nanometres, with 1 nanometre being equal to 1 billionth of a metre. In the visible spectrum, the colour red is made up the longest visible wavelengths.

However, beyond wavelengths of about 700 nanometres, we can no longer see the colour red, and it is in this range of frequencies (immediately beyond visible red) that most thermal imagers work. In practice though, thermal imagers work by calculating the effective temperature of an object by comparing the intensity of emitted radiation caused by heat with that of a perfect blackbody, which is a theoretical object that absorbs all of the electromagnetic radiation that strikes it.

Nonetheless, even though an object such as a brake rotor or exhaust manifold may be hot enough to emit invisible infrared radiation, the emissivity of the hot material plays a critical role in how accurately a thermal imaging device can calculate the objects’ temperature. Put in another way, this means that if say, five objects made of different materials are heated to the same temperature, each object will emit a different level of infrared radiation because they have different emissivity values.

As a rule of thumb, most objects and surfaces found in motor vehicles typically have emissivity values that range from about 0.1 to about 0.95, depending on the surface condition of the object or surface. However, these values are not absolute since factors such as the chemical makeup of the object, ambient temperature, and the observers’ viewing angle can all influence temperature calculations.

To address these variables, most professional grade thermal imagers will have several preset choices to allow the user to choose the setting that most accurately corresponds to the actual surface condition of the object being observed. Typical presets could include Aluminium, Cast Iron, Polished, Corroded, etc, etc, and provided an appropriate choice is made by the user, most thermal imagers will return a temperature value that falls within a few degrees of the objects’ actual temperature, which will be displayed as a part of the image.

At this point, it might be beneficial to inexperienced users of thermal imagers to say something about the colours these tools display. On most imagers, the colours a user sees is known as a “colour palette” in which each colour represents the temperature of the objects in the display, although all the visible colours in a thermal image may not always represent a true temperature value. Generally though, display colours usually run from blue to white, with blue being the coolest, red being warmer, orange being warmer still, yellow being warmer than orange, and white being the hottest, since white is a mixture of all the colours (light frequencies) emitted by the object.

However, it must be noted that in some cases, the temperature of an object may not differ enough from its surroundings so that it would show up in a colour display. Thus, most high-end thermal imagers include a gray-scale, or black-and white display option in which temperature differences show up as distinctly different shades of grey.

Now that we understand the basic principles of thermal imaging, let us look at some practical examples of how it can be used as a diagnostic tool-

As mentioned elsewhere, parasitic battery drains and many other electrical issues can be really tricky to find and resolve, but since the flow of electricity through circuits generate a fair amount of heat, a thermal imager can be used to-

Identify a relay that is stuck closed

Simply point the imager at a fuse box, and the defective relay will show up as a hot spot compared to its surroundings.

Identify short circuits

If all circuits in the vehicle are deactivated long enough for all residual current to have drained off, fuses and/or fusible links that show up as hot spots in a thermal image will identify the circuit(s) that contain short circuits.

Identify open circuits

Since these can sometimes be difficult to find in window defogging elements and heated seats, scanning the window or seat while the elements are activated will immediately show the site of the break, or interruption in continuity.

Identify bad ignition coils

Since the first sign of a bad, defective, or failing ignition coil is usually a rise in its temperature, the bad coil will show up as a spot that is hotter than the other coils.

Identify poor electrical connections

Since poor connections and particularly ground connections get hot because of arcing, any bad connections will show up as bright spot in the displayed image. This is particularly useful in cases where bad connections are buried deep inside wiring harnesses; in most cases, the poor connection will heat up the surrounding wiring and while a thermal imager may not be able to identify the actual wire in a harness that contains the bad connection, the displayed hot spot will identify the site of the bad connection.

Identify poor internal battery connections

When a load is placed on the battery the temperature of a poor connection will increase, which will show up as a hot spot in a thermal image.

Since all components in a vehicle that move, rotate, or slide relative to other surfaces generate heat through friction, convection, or radiation, a thermal imager can identify potential issues long before they become actual problems. Below are some practical examples of how a thermal imager can be used to-

Identify bad or damaged wheel bearings

Not all damaged wheel bearings are noisy, but a damaged wheel bearing will always run hotter than a bearing that is in good condition. Thus, by comparing the heat signatures of say, the front wheel bearings, the damaged bearing can be identified without dismantling the hub.

Identify dragging/binding brakes

Sometimes, the drag may be so slight that it goes unnoticed by the driver, but even in these cases, a thermal imager will clearly demonstrate the temperature difference between two or more brake rotors/drums.

Identify mis-aligned wheels

Since the rolling resistance of a misaligned wheel is higher than the resistance of properly aligned wheels, the increased rolling resistance will show up as a temperature difference between two or more tyres in a thermal image.

Identify worn or damaged shock absorbers

Since all shock absorbers get hot when they are worked hard, the temperatures of the shock absorbers on any given axle should match each other very closely. Thus, if one shock absorber on an axle is colder than the other is, the colder shock absorber is likely damaged or worn.

Identify slipping drive belts

Since slipping drive belts generate a great deal of heat, a thermal image will reveal the point where the slippage is greatest, with the most common sites being small-diameter idler or alternator pulleys.

Identify cylinders with poor combustion

While most combustion issues will set one or more trouble codes, some combustion issues do not. For instance, a marginally defective fuel injector may not affect combustion to the point where an actual misfire occurs, but in these cases, a thermal image will clearly show a temperature difference between the exhaust manifold runners, with the affected cylinders’ runner being colder than the others are.

This list of examples is not exhaustive, but it should serve to illustrate the point that a thermal imager can diagnose issues that in many cases cannot be diagnosed with other methods, some of which could take many hours of sleuthing, dismantling, testing, and/or retesting, which brings us to-

Thermal imagers are not created equal, and there are several things to consider before investing in one. Here is a quick rundown of what to be aware of, and what to look out for-

The imager must include a known-good library

Reputable manufacturers of thermal imagers that are designed to be used in the car repair trade include an extensive library of images of parts and components that are known to be good. These would typically consist of several hundred thermal images of brake rotors that are uniformly heated, engine-cooling systems in which the coolant is circulating freely, cabin heater cores that are known not to contain blockages and restrictions, and A/C systems that are fully functional, etc.

These images are valuable reference sources, and the more there are, the easier it becomes to eliminate false positives.

The imager must operate over a wide heat range

While subzero temperatures are usually not an issue in the Australian context, it is nevertheless useful to have an instrument that can register temperatures from as low as about -200C, to about 4500C to 5000C. The lower end of such a scale is useful to test A/C systems, while the high upper end is useful to test catalytic converters and other hot exhaust components, such as diesel particulate filters.

The image must have the biggest available thermal sensor

Some of the specs in adverts can be misleading; in many cases, the manufacturer will say its products have resolutions of say, 320 × 240 pixels, but be aware that this often refers to the display, and NOT to the thermal sensor.

Put simply, the bigger the thermal sensor is, the higher the resolution of the displayed image becomes. While there are many automotive-grade thermal imagers on the market that use thermal sensors that are 320 × 240 pixels big, it often happens that electronic noise or other external factors conspire to produce an ill-defined blob of heat energy without any useable detail.

The next step up is a thermal sensor of 640 × 280 pixels, and although such an instrument can cost as much as a high-end scan tool, the collecting power of 307 200 pixels ensures clear images in which minute temperature differences and structural details are clearly visible, which is generally not possible to do with lower-resolution thermal sensors.

While it might appear from the above that thermal imagers are difficult to use, the fact is that in most cases, you merely point the instrument at something and pull the trigger to generate an image that could save you hours of diagnostic time and tons of money in terms of faster turnaround times, increased productivity, and improved customer satisfaction.