Stoichometric/Lambda: This is the ideal air/fuel ratio for any given fuel type. Different fuel types have different ideal air/fuel ratios.

Narrowband: An o2 sensor that typically operates within a narrow spectrum and is capable of determining either lean, stoichometric or rich mixture.

Wideband: An o2 sensor that typically operates within a wide spectrum and is capable of determining air/fuel ratio.

Open Loop: When the engine ECU is ignoring what the o2 sensor is telling it.This may be due to a cold engine, fault condition etc.

Closed Loop: When the engine ECU is listening to what the o2 sensor is telling it and making adjustments accordingly.

...let's quickly take a look at our conventional narrowband sensor.

After all, a wideband o2 sensor is really just a narrowband sensor with some ‘extra fruit’

Narrowband sensors are great at telling us whether an engine is running rich or lean. The problem is they can't really tell us HOW rich or lean. So it is a fair comment to say ‘A narrowband sensor only knows when the mixture is ‘just right’

Because we never know how rich or lean an engine is running with a narrowband sensor, the ECU is constantly making the engine run very marginally rich, then lean, then rich, then lean, so on and so-forth to straddle that stoichiometric mixture point. This is why when an o2 sensor is in closed loop we see our typical switching pattern as shown below, the ECU does this so it knows ‘where the mixture is’

This (cross-counts) all happens multiple times per second , so although it looks a little crazy on our live data trace, when we look at an this on an exhaust gas analyser we get a relativley smooth stoichiometric mixture reading.

‘A wideband sensor knows exactly what the mixture is'

While a narrowband sensor can only measure marginally either side of Lambda, a wideband can measure from about 5:1 to about 20:1 which provides great feedback for all engines, but particularly diesel, direct petrol injection and forced induction applications.

Now, remember how we said that a narrowband sensor only knows when the mixture is ‘just right’? It can't tell how rich or lean our engine is, right?

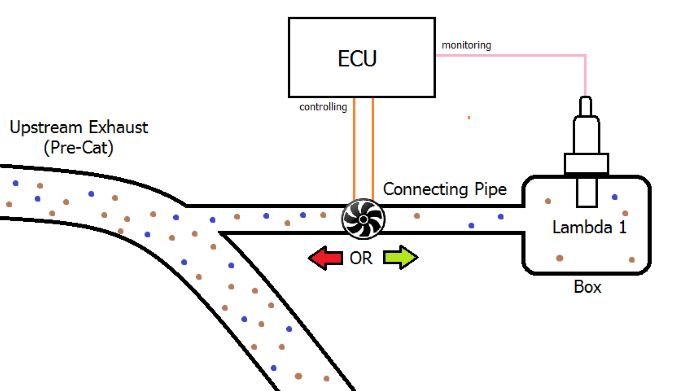

For the sake of this example, lets say we stick our narrowband sensor in a box outside of the exhaust and we put a pipe between our box and the exhaust.

In the middle of this pipe, we put a fan. Now the ECU has a new job; to always keep that box at a stoichiometric air/fuel ratio.

To change which way the fan blows, we change the direction of current flow by changing the polarity (cross the wires over on our fan)

To increase how fast the fan spins, we adjust the current.

The ECU makes these adjustments to the fan current (amount and direction) based on the feedback from the measurement at the box.

By measuring how much current is required to acheive a stoichometric mixture in the box, we know the air/fuel ratio that our engine is running at.

So obviously there is no box, fan or tubes and this example is technically innaccurate, but we hope it helps to visualise how a wideband functions.

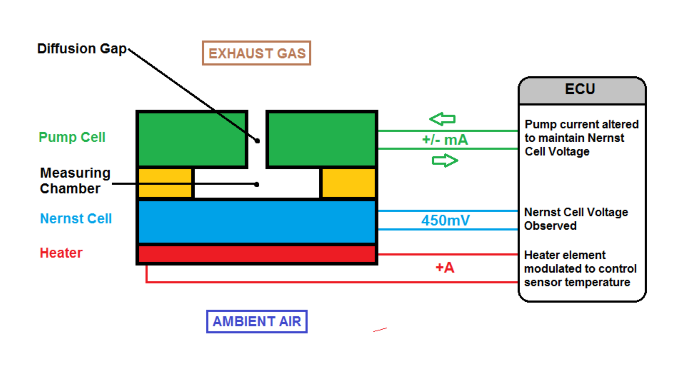

The box is known as the nernst cell. Whenever the voltage of the nernst cell deviates from the set voltage (typically 450mV) the pump cell will start to work to correct it.

The fan is known as the pump cell and is controlled by the ECU to keep the nernst cell at a fixed voltage.

What does it all look like in the sensor?

Pretty damn small and pretty damn boring actually.

If we were to look at a cross-section of a modern wideband o2 sensor it would look something like this...

If we were to break down the sensor operation into functional steps, it would look something like this:

-) Heater is activated to maintain operational temperature of sensor (>300C)

1) Exhaust gas enters measuring chamber through diffusion gap.

2) ECU checks Nernst voltage.

3) ECU corrects Nernst voltage by activating the pump cell to move exhaust gas in or out of the measuring chamber.

4) ECU checks how much pumping current it had to apply to correct the nernst voltage.

5) ECU makes adjustment to fuelling

So 14.7:1 isnt always lambda 1?

No, different types of fuels require a different air/fuel ratio to acheive lambda 1 and they are as follows:

A misfire will cause a cylinder to read lean?

This is often reffered to as a 'false lean'

Keep in mind there are a number of different causes of misfires (secondary ignition fault, retarded timing, bad injector spray pattern etc) and variables that can influence how a sensor interprets a running condition.

If we were to look at a complete cylinder misfire (no ignition event) on a gas analyser we would see an increase in both oxygen (02) and hydrocarbons (HC)

How can there be unburnt fuel aswell as enough oxygen left to burn it unless we had a misfire?

This would not occur if the engine was actually lean.

Unfortunatley, an engine management computer cannot see hydrocarbon concentration, it only sees a lean condition so it's answer was to typically add more fuel, which further exacerbates the problem.

Nowdays, misfire monitoring is a bit more sophisticated and most ECU's will shut a cylinder down in the event it detects a misfire to prevent problems such as washing down cylinders with fuel.

Mechanic Top Tips!

Thanks for taking the time to read this article and we hope it made wideband oxygen sensor operation a little clearer!

If you have any feedback, please shoot us an e-mail at [email protected]